Sodium-ion batteries are rechargeable batteries that work similarly to lithium-ion batteries in that they rely on movement between the positive and negative electrodes. In addition, the overall process flow of sodium-ion battery is similar to that of lithium-ion battery, which is generally divided into raw material preparation, electrode preparation, battery assembly, finished product testing and other steps, among which electrode preparation is the focus of the production process of sodium-ion battery, involving multiple core links in the production process.

The production process of sodium-ion batteries can be roughly divided into the following stages:

1. Preparation of raw materials: including cathode materials, anode materials, electrolytes, separators and battery shells, etc. The cathode material usually uses layered oxides, polyanionic compounds, etc., while the anode material may use carbon materials, alloy materials, etc.

2. Preparation of positive and negative electrodes: The preparation of positive electrodes usually uses layered oxides, polyanionic compounds and other materials to improve their electrochemical properties by controlling the synthesis conditions and doping modification. Carbon materials, alloy materials, etc. are usually used for the preparation of anodes, and their electrochemical properties are improved by controlling the pores and specific surface area.

3. Electrode preparation: The positive and negative electrode materials are coated on metal foils, followed by a process of drying and rolling. In this process, the thickness and uniformity of the coating need to be controlled to ensure the consistency and stability of the electrode.

4. Assembling the battery: Before assembling the battery, an electrolyte needs to be injected into the battery case. Then, the positive and negative electrodes are placed on both sides of the electrolyte, and they are connected to the battery case by welding, etc. Finally, the sealing and filling operations are carried out to complete the assembly of the battery.

5. Battery testing: Once assembly, the battery needs to be tested to ensure that it performs as designed. The test items include voltage test, charge and discharge test, cycle life test, etc.

6. Chemical selection: including pre-packaging, formation, secondary packaging, volume screening and other steps.

The status quo of technology investment in the industry

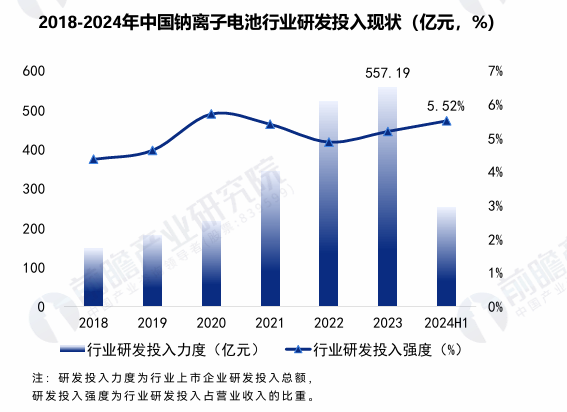

From 2018 to 2023, the scale of investment by manufacturers in China's sodium-ion battery industry has shown a trend of increasing year by year, and has maintained a high growth rate. At the same time, the intensity of R&D investment in the industry has also shown the characteristics of fluctuating growth, and by 2023, its R&D investment scale has increased to 55.719 billion yuan. In terms of R&D personnel, by 2023, the average number of R&D teams owned by listed companies in China's sodium-ion battery industry has reached 1,055, which strongly proves that the scale of R&D teams in the industry is growing.

Figure: R&D investment status of China's sodium-ion battery industry from 2018 to 2024 (Source: Forward Industry Research Institute)

According to incoPat, from 2011 to 2024, the number of patent applications and publications for sodium-ion batteries in China has shown a fluctuating upward trend. In 2023, the number of patent applications for sodium-ion batteries in China will reach 3,446, marking that patent applications in this field have entered an explosive stage. As of October 2024, Central South University has become the institution with the largest number of patent applications in the field of sodium-ion batteries, with a total of 410 related patent applications recorded.

Demand scenarios in different fields

In the field of power, sodium-ion batteries are very suitable for low-speed trams, such as electric bicycles, electric tricycles, etc., due to their low cost and strong safety. According to market research, from 2018 to 2023, the sales of pure electric vehicles in China will increase year by year, reaching 6.685 million units in 2023. In addition, the sales of two-wheeled pure electric vehicles are also showing a steady upward trend, according to the forecast of the Prospective Industry Research Institute, by 2029, the demand prospect of sodium-ion batteries in China's power field will reach 38GWh, with a market size of about 15.2 billion yuan.

Figure: 2024-2029 demand prospect of sodium-ion batteries in China's power field (GWh, 100 million yuan)

In the field of energy storage, the energy storage field is a key area for the commercial application of sodium-ion batteries in China, and the energy storage industry has entered a stage of rapid development in 2021, and the application of sodium-ion batteries in energy storage power stations is also gradually increasing, especially in the fields of renewable energy access, household and industrial energy storage, 5G communication base stations and data centers. Due to the relatively low energy density requirements in the field of energy storage and the fact that it is more sensitive to cost, the low-cost advantage of sodium-ion batteries makes it have broad application prospects in this field. According to the Prospective Industry Research Institute, the scale of sodium-ion battery energy storage is expected to grow rapidly in the short and medium term, and preliminary statistics show that by 2029, the application scale of China's sodium-ion battery field will be close to 2500MWh.

Related:

2024 China Sodium-ion Battery Report (1)

2024 China Sodium-ion Battery Report (2)

2024 China Sodium-ion Battery Report (3)