In today's rapidly evolving technology environment, the demand for smaller, more powerful electronic devices is driving the rapid growth of the global 3D semiconductor packaging market. As a compact and efficient solution in the modern electronics industry, 3D packaging technology is becoming increasingly influential.

As devices continue to miniaturize, 3D packaging has become a key technology for integrating multiple chips into a single package, bringing many advantages over traditional 2D packaging. In 2023, the global 3D semiconductor packaging market has reached $11 billion and is expected to grow to $57.19 billion by 2034, growing at a CAGR of 16.17% between 2024 and 2033.

The rapid expansion of the 3D packaging market in recent years has been driven by the Asia-Pacific region, especially with the contribution of semiconductor manufacturing powerhouses such as China, Japan and Korea, which play a key role in the future development of 3D packaging technology. At the same time, the North American market is also growing rapidly, especially in the high-performance computing, data center, and automotive sectors, where demand for semiconductor technology is surging.

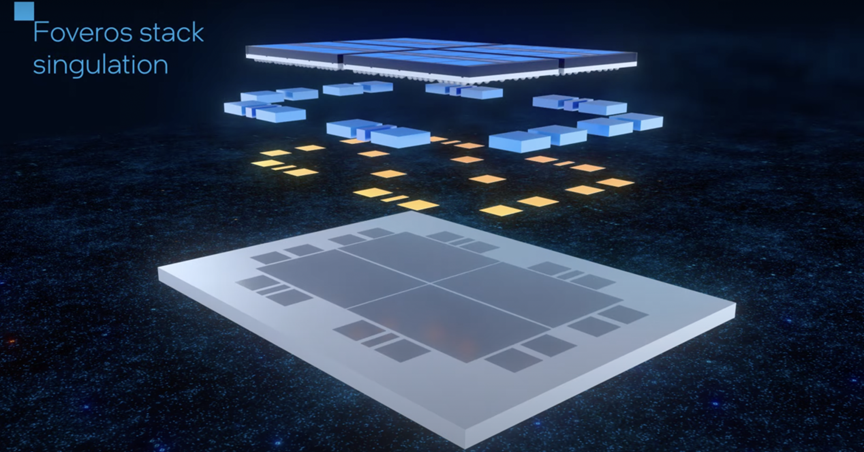

Key technologies for 3D packaging include:

1. Through-silicon vias (TSVs): Vertical electrical connections through silicon wafers increase data bandwidth and reduce power consumption.

2. Wafer-Level Packaging (WLP): Package directly on the wafer to improve performance and reduce costs.

3. System-in-Package (SiP): Integrates multiple semiconductor devices in a single package, providing design flexibility.

4. Chip-on-Wafer (CoW) and Wafer-on-Wafer (WoW): Further increase package density.

Figure: Demand for electrical equipment is driving 3D packaging

The core advantages of 3D semiconductor packaging are:

Space efficiency and miniaturization: By stacking chips vertically, the device size can be significantly reduced, meeting the needs of small devices such as smartphones, tablets, and wearables.

Performance improvement: Shortens the distance between chips, reduces latency, and increases data bandwidth, making it suitable for applications that require high processing power, such as cloud computing and artificial intelligence.

Thermal Management Optimization: By improving heat distribution, it effectively prevents overheating and ensures the stability and longevity of the equipment.

In terms of market distribution, 3D through-silicon via (TSV) technology dominated the market in 2023, gaining popularity due to its efficient high-speed data transmission and low power consumption. It is expected that this technology will continue to dominate the market in the future. At the same time, organic substrates will also see significant growth in the coming years, mainly due to their excellent performance and low cost in dealing with the thermal stress of the chip.

In industrial applications, the automotive and transportation industry is the largest market share holder of 3D packaging in 2023. With the development of autonomous driving, electric vehicles, and connected car technologies, the demand for high-performance semiconductors has increased significantly, driving the growth of this field.

Overall, the demand for miniaturized and high-performance electronic devices will continue to drive the development of 3D semiconductor packaging technology. In the future, 3D packaging will play a vital role in the future of semiconductor design and manufacturing as technology advances and the industry explores more compact and powerful solutions. In terms of industrial verticals, the Automotive & Transportation industry accounted for the largest share of the 3D semiconductor packaging market in 2023. With the increasing adoption of autonomous, electric and connected car technologies, the demand for high-performance semiconductor solutions has surged, making the automotive industry a key market driver.

The demand for miniaturized, high-performance electronic devices is driving the growth of the 3D semiconductor packaging market. As technology advances and industries seek more compact, efficient, and robust solutions, 3D packaging will play a key role in shaping the future of semiconductor design and manufacturing.