IGBT is called "CPU" in the field of power electronics, and it is the core component of electric vehicles, photovoltaics and energy storage. In recent years, driven by new energy industries such as electric vehicles and photovoltaics, IGBT has ushered in a new development peak, and China has also become the largest IGBT demand market in the world. At present, the supply of IGBT is still tight. It has been reported that the shortage of IGBT chips may last until the first half of next year. It is generally believed in the industry that in the future, with more and more Chinese IGBT manufacturers joining, more domestic IGBT products with high costs performance will enter the global supply chain, thus alleviating the supply shortage.

The "Heart" of New Energy Vehicles

IGBT and power battery cells are called "twin-core" of electric vehicles, which are the key components that affect the performance of electric vehicles. It is understood that the number of IGBT used in electric vehicles is as high as hundreds, which is 7 ~ 10 times that of traditional fuel vehicles. Its cost accounts for 7% ~ 10% of the whole vehicle cost.

In recent years, the production and sales of new energy automobile industry are booming, becoming the largest incremental market of IGBT. According to the data of China Association of Automobile Manufacturers, China's new energy automobile industry continued to explode in 2022, with production and sales of 7.058 million vehicles and 6.887 million vehicles respectively, up by about 97% and 93% year-on-year. China Automobile Association predicts that the total sales volume of new energy vehicles in China is expected to exceed 9 million in 2023. Relevant data show that the market share of IGBT for new energy vehicles will reach 39.7% in 2022, making it the largest market for downstream applications of IGBT, and it is estimated that the market share will be close to 49% by 2025.

AIONLX plus IGBT, a subsidiary of GAC AION, is a composite power semiconductor device composed of bipolar triode (BJT) and MOSFET, which is called CPU in the field of power electronics. "The main function of power semiconductor is to convert energy, including regulating current, voltage, frequency, DC or AC, etc. IGBT can output relatively high current under the condition of low loss, which is very suitable for scenes where high current and high voltage coexist, such as new energy vehicles, wind and solar storage and charging, etc. " Lei Guangyin, a researcher at Fudan University Institute of Engineering and Applied Technology, said.

It is understood that IGBT is mainly used in motor controllers and charging piles of new energy vehicles, and IGBT is the core component of motor controllers, accounting for 40% ~ 50% of its overall cost. It provides power for electric vehicles by controlling current through high-frequency, high-speed and high-voltage switches. In addition to motor control, IGBT is also applied to charging piles of electric vehicles. Lei Guangyin introduced: "The alternating current from the power grid has the characteristics of high voltage and large current, which is not suitable for charging the power battery directly. It needs to go through a series of rectification, boosting and frequency conversion processes and be converted into the output power that meets the requirements before charging. This process cannot be separated from the support of power semiconductors. IGBT can control high voltage and large current to ensure the maximum charging speed and efficiency of batteries. "

Although an IGBT module is the smallest but palm-sized, it is the lifeblood of "driving" the motor controller. IGBT is the key to the acceleration ability, top speed and energy efficiency of electric vehicles. "New energy vehicles need electricity to drive, and the function of IGBT is to distribute current to motors. When we step on the accelerator deeply, it will distribute more current to the motor, which makes the electric locomotive accelerate faster. " Wu Haiping, director of chip research and development of BYD Semiconductor Power Semiconductor Product Center, said.

“ Photothermal storage” makes IGBT went viral

The relevant person in charge of SUN.KING Technology said that "carbon neutrality" has become a global consensus. In order to achieve this goal, it is necessary to take relevant measures in power generation, transmission and distribution, and electricity consumption, so as to build a sustainable green energy development system. IGBT, as the core component of photovoltaic inverter, will be directly driven by the development of this market. "This year, the demand for IGBT for electric vehicles has entered a period of gentle growth, but the demand for light and wind storage (photovoltaic, wind power, energy storage) is still very strong, and the market scale is growing rapidly." The leader said.

China Photovoltaic Industry Association predicts that the newly installed capacity of photovoltaic inverters in the world is expected to reach 330GW in 2025. According to the analysis of Zheshang Securities, according to the calculation that IGBT accounts for 18% and 15% of BOM cost (material cost) of series inverters and centralized inverters, it is estimated that the global IGBT market for photovoltaic inverters will expand at a growth rate of 17.6%, and the market scale will exceed 10 billion by 2025.

2010-2022 Cumulative installed PV capacity in China

Photovoltaic inverter is the heart of solar photovoltaic system, and IGBT is the lifeblood of photovoltaic inverter. In recent years, the rapid growth of photovoltaic installed capacity has greatly increased the demand for inverters and further opened up the IGBT market. It is understood that the main function of photovoltaic inverter is to convert DC power generated by photovoltaic system into AC power that meets the power quality requirements of power grid, and finally merge into power grid. Its performance can affect the stability, power generation efficiency and service life of the whole photovoltaic system. IGBT can control each power device turn on and off, and then step up or step down through transformer coupling, finally realize AC/DC conversion.

The "high prosperity" of energy storage also brings new market opportunities for IGBT. Lei Guangyin pointed out that "integration of light and storage" has become the general trend, and the allocation of energy storage has become a prerequisite for grid-connected photovoltaic power stations. Unlike photovoltaic inverter, which can only convert DC into AC in one direction, energy storage inverter has bidirectional energy control function of charging and discharging. "The principle of 'Optical Storage' is similar to the principle of 'Charging and Storage' of electric vehicle charging piles. The main functions of IGBT are voltage transformation, frequency conversion and alternating conversion." Lei Guangyin said.

It is worth mentioning that the service life of IGBT and other electronic components in photovoltaic inverters is generally 10 ~ 15 years, while the operation cycle of photovoltaic modules is 25 years, so inverters need to be replaced at least once in the life cycle of photovoltaic modules, which further expands the use of IGBT in photovoltaic systems.

"In the next decade, electrification and digitalization will become important driving forces for industrial and social development. Electrification involves all links of power value chain including power generation, power transmission and transformation, energy storage and electricity consumption. Power semiconductors, including IGBT, play an important role in the whole power value chain. With the advancement of electrification, the market scale of power semiconductors will continue to grow in the future. " The relevant person in charge of INFINEON said.

IGBT under the tide of electrification

Recently, the news about IGBT shortage broke out from time to time. There is even news that the gap between supply and demand of IGBT is close to 50%. In this regard, Lei Guangyin rumored that although IGBT is in short supply, the actual situation is not so exaggerated. In fact, IGBT shortage has existed for a long time. As early as 2021, data showed that the gap between IGBT supply and demand in China exceeded 100 million. After entering 2023, the shortage of IGBT has not improved. At present, the supply of IGBT products is in short supply, the existing production capacity has been basically sold out, and the pressure to guarantee supply is great. The new expansion orders have been locked in advance by downstream manufacturers.

It is generally believed in the industry that the mismatch between supply and demand is an important reason for the continuous shortage of IGBT. Yin Rongfang, CEO of Shouhang New Energy, pointed out that the semiconductor industry is expanding at an annual rate of 8% ~ 10%, while photovoltaic and energy storage are expanding at an annual rate of 30 ~ 50%. Coupled with the explosive growth of new energy vehicles, the growth rate of downstream demand far exceeds the growth rate of upstream supply, resulting in tight supply and demand of IGBT in the whole market. Li Guoqiang, research director of ICWISE, said: "The main reason for the shortage of IGBT in this round is the rise of new energy vehicles, the demand for high voltage has increased greatly, and IGBT has become the focus of industrial development."

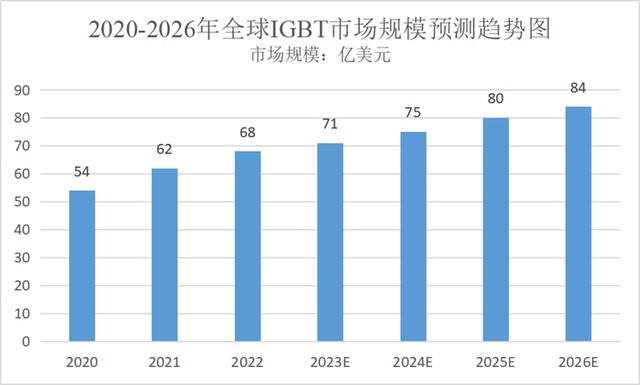

Forecast of global IGBT market sizes

In Lei Guangyin's view, the failure of Chinese enterprises to deeply participate in IGBT global industrial chain supply chain is one of the important reasons for the mismatch between supply and demand. "China's IGBT has long relied on imports. Previously, the imported products of vehicle-level IGBT once accounted for 90%. In recent years, China's new energy industry has developed rapidly, especially the new energy automobile industry has increased by nearly 50% in the past 5 to 10 years, and the production and sales last year even increased by more than 90% year-on-year. This is unexpected for overseas manufacturers, so there is no way to expand production in time. In addition, overseas manufacturers generally adopt a conservative attitude towards market expansion and will not expand production easily. " Lei Guangyin pointed out.

"The capacity expansion of foreign manufacturers cannot keep up with the rapid development of the industry, which is also the reason for the imbalance between supply and demand." A photovoltaic practitioner said. Previously, IGBT market has been occupied by foreign companies with deep accumulation for a long time, and INFINEON, FUJI, ONSEMI, TOSHIBA, STMICROELECTRONIICS and other companies have occupied most of the market. However, the continuous shortage of IGBT market provides opportunities for Chinese enterprises. Since last year, Chinese IGBT enterprises began to receive a large number of orders from new energy vehicles and photovoltaics.

Industry insiders said: "Semiconductor chips sound like high-end, but in fact, the design of IGBT, especially single tube, is not complicated. With the increase of shipments of domestic enterprises, the process is relatively stable, and the manufacturing links are highly automated, which is basically closer and closer to the mass production of foreign brands. "

Application Scenario of BYD Semiconductor Photovoltaic Inverter Special IGBT

"At present, many domestic enterprises are doing IGBT and have achieved certain results. IGBT in low-power household inverters can be supplied by domestic enterprises, and there are many domestic suppliers of high-power centralized inverters IGBT. However, because of the large current, high switching frequency and highly power density, there is no suitable IGBT manufacturer in China at present, which will become the final research direction of IGBT. I believe there will be qualified suppliers in China in 1-2 years. " The above photovoltaic practitioners said.

The attention of domestic policy is also one of the important driving forces for the rapid development of domestic IGBT. The 14th Five-Year Plan for National Economic and Social Development of the People's Republic of China and the Outline of Long-term Goals in 2035 require that superior resources should be concentrated to tackle key core technologies in the fields of key components and basic materials, and the development of IGBT and wide band gap semiconductors such as silicon carbide and gallium nitride should be emphasized.

The Guiding Opinions on Promoting the Development of Energy Electronics Industry jointly issued by the Ministry of Industry and Information Technology and other six departments pointed out that key breakthroughs in the fields of basic components, basic materials and basic processes should be promoted, and basic electronic components such as miniaturized, high-performance, high-efficiency and high-reliability power semiconductors should be studied. For photovoltaic, wind power, energy storage systems, etc., develop IGBT devices and modules with high temperature resistance, high voltage resistance, low loss and high reliability for new energy.

Regarding the future supply of IGBT, Lei Guangyin said optimistically: "At present, more and more Chinese manufacturers begin to develop and manufacture IGBT. After several years of experience, I believe more domestic IGBT products with high costs performance will enter the global supply chain to alleviate the supply shortage. "

IGBT under the wave of electrification: the experience of Chinese manufacturers-China exportsemi.com