MCU (Microcontroller Unit) is a widely used fundamental control chip situated at the core of electronic systems. Its performance parameters play a decisive role in electronic systems, making it an indispensable core component for various circuit systems. In recent years, the market potential of MCU is gradually prominent. According to IC Insights data and forecast, the global MCU market will be about 19.6 billion US dollars in 2021, up 23.4% year-on-year, and it is estimated that it will reach 27.2 billion US dollars with a compound growth rate of 6.7% by 2026. With the continuously expanding market size compounded by the influence of geopolitical factors, domestically produced MCU products are poised to usher in a new peak of applications

On the one hand, in order to improve the safety factor of supply chain, the end customers in various industries in China are more willing to use domestic MCU, and have launched more extensive cooperation with domestic MCU enterprises. Especially in 2021, in the tide of global core shortage and price increase, many overseas MCU leading manufacture products have high prices and unclear delivery dates, and many terminal equipment shipments are blocked. Chinese MCU enterprises have fully grasped this opportunity and signed many orders from end customers. Due to the long cycle and high reintroduction costs of ecosystem construction in MCU applications, the 'order import' brought about by this wave of local supply is particularly valuable for domestic MCU manufacturers. It also opens up a broader perspective for large-scale verification of the performance of domestically produced MCU products

On the other hand, after years of development, local MCU enterprises have gradually matured in technology and product ecology. In recent years, they have grasped the needs of domestic emerging markets in place, and their services have been widely recognized by domestic customers.

Under the double benefits, how will domestic enterprises make persistent efforts to seize new markets for MCU products? On July 6th, Guangdong SYNWIT Co., Ltd., a well-known MCU enterprise in China, shared its market layout and service strategy at the 2023 agent product exchange meeting.

Figure1: product seminar

Three major product lines to create domestic MCU stars

According to Zhang Zhuo, marketing director of SYNWIT, the company has entered the MCU industry since 2014, and its core technical teams have more than ten years of experience in chip design. The team has rich practical accumulation and solid theoretical knowledge in CPU, storage, low power processor, AD, POWER, ESD and so on.

In terms of product research and development, SYNWIT focuses on the research and development of 32-bit MCU. At present, based on ARM ® Cortex ®-M0, Cortex ®-M4 and Cortex ®-M33 cores, it has launched several series of MCU products for motor control, TFT-LCD control, major appliance, intelligent control and industrial control instruments.

Figure2: Zhang Zhuo introduces product development way of SYNWIT

According to the company's product roadmap, unlike most MCU manufacturers in China who cut into the consumer electronics market, SYNWIT chose industrial computer and motor MCU with higher research and development difficulty at the beginning of its establishment. After years of layout, its product line is mainly divided into three series: screen drive, motor and general purpose.

- Screen drive MCU

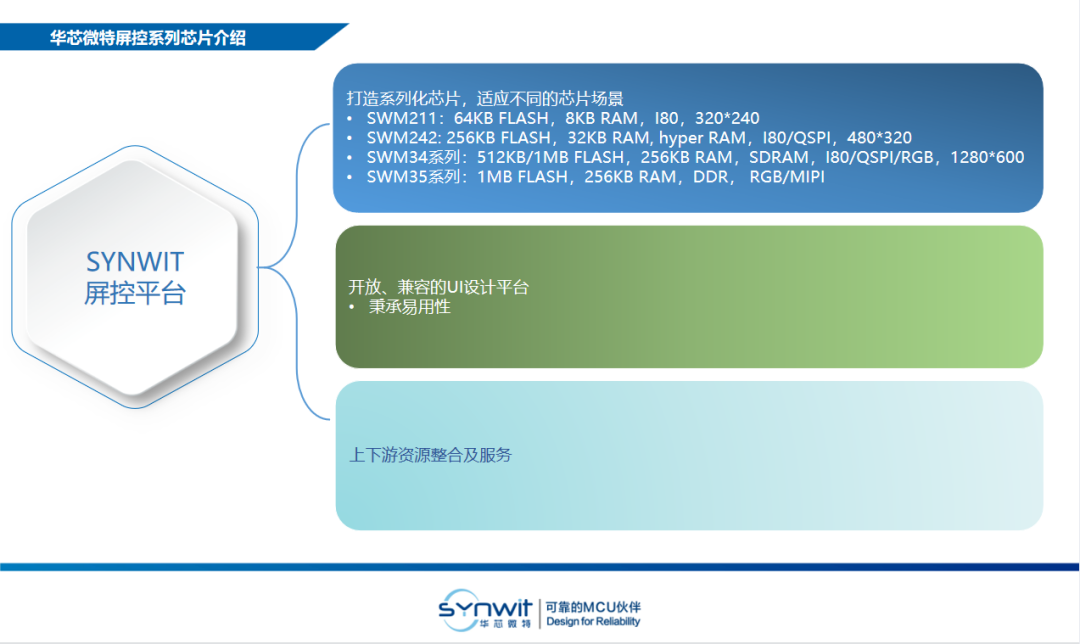

Screen drive MCU is a unique product series of SYNWIT At present, SYNWIT has served more than 800 customers in the field of screen-driven MCU, and has successfully entered the first camp of domestic screen-driven MCU track. Screen drive MCU is mainly responsible for controlling the display of key information in the screen display system. In order to meet the needs of screen scenes with different sizes and resolutions, SYNWIT team has created three series of MCUs: SWM19S, SWM32S and SWM34S.

Figure3: SYNWIT special screen control platform

With rich product materials and high performance, SWM19S and SWM32S series of screen drive MCU introduced in the early stage are well received applications in small and medium-sized TFT-LCD screen drive applications, and are widely used in 86 boxes, household appliances, ventilators, electric vehicles, card readers and intelligent lighting modules.

In September 2021, SYNWIT added a new member of SWM34S series chips to its screen drive MCU family for TFTLCD screen driver. It is understood that SWM34S is a 32-bit MCU based on ARM Cortex-M33, which has the characteristics of high performance, low power consumption and high code density, and is suitable for LCD drive, industrial control, major appliance, motor drive and other application fields.

In the field of screen drive, with the deepening understanding of the needs of refined scenes and the accumulation of technology, the research and development of SYNWIT is still accelerating. According to reports, SWM342, a new product of SWM34S series chips, is planned to be launched from 2023 to 2024. While improving the performance parameters, the new product will also provide customers with more cost-effective choices, and continuously meet the application requirements of small and medium-sized screens of terminal equipment such as coffee machines, microwave ovens, water dispensers, sweepers, washing machines, hand-held POS machines, electric vehicle instruments, ventilators and life detectors.

- Motor control MCU

Liu Peng, product manager of motor product line, said that the market potential of motor control MCU is huge. The average number of motors owned by each family in developed countries is 80 to 130, while the average number of motors owned by families in big cities in China is about 20 to 40, which is far lower than the average level in developed countries.

In the motor market, the penetration rate of BLDC is getting higher and higher. The biggest difference between BLDC motor and AC motor is that it needs control and drive system. SYNWIT began to lay out the motor control MCU market in 2017, and its products iterated from SWM190 to SWM201 to SWM211. The product has perfect function and performance, high reliability and stability, and is closer to the market demand.

In order to better meet the needs of customers, SYNWIT independently developed the motor algorithm, and all motor projects except individual chips support customers are developed based on this algorithm platform. At present, SYNWIT Micro Motor Control MCU can be applied to electronic equipment such as high-speed air duct, high-speed vacuum cleaner, air purifier, floor fan, air conditioner fan, range hood, exhaust fan, toilet air dryer, fresh air system, etc. "Motor control market is more rat race" Zhang Wei said frankly, "The company is still improving its product competitiveness in the field of motor control. Next year, we intend to provide motor control MCU and supporting power devices to the car-level market."

- Universal MCU

The general MCU products of HSYNWIT mainly include SWM181, SWM320, SWM260, SWM241 and other series models, and the next generation products SWM242 and SWM182 are accelerating research and development. According to Zhang Zhuo, general MCU of SYNWIT is mainly used in the household appliance market. For a long time, MCU of domestic household appliances brands has been basically occupied by overseas manufacturers. To deal with this situation, SYNWIT has put forward targeted alternatives, which have achieved results so far. It is understood that SYNWIT has obtained orders from many well-known household appliance brands. In the monthly quality assessment of a domestic head appliance brand, SYNWIT MCU ranked first in quality score for two consecutive years.

Zhang Zhuo emphasized that "the company has been researching and developing industrial control products since its inception, and team technology has accumulated deeply in this field. The industrial control field has high requirements for product performance reliability, which makes the company follow this technical characteristic in other series of products. All products of the company take reliability as an important consideration at the beginning of research and development, and ensure product reliability with strict verification and testing. High reliability products are a great weapon for us to gain customers' trust. "

Improve the service ecology and work together to create value

There are many giants in MCU field, so it is not easy to occupy a place in the track with many giants. It is not enough to have only high-quality products and rich product matrix. SYNWIT is strengthening products and services in different links. SYNWIT officially launched the "123 Screen Drive Training Action" at this conference. Jiang Xu, sales director of SYNWIT in South China, said that it aims to strengthen cooperation with agents, work together to improve the service level of screen drive market, and jointly achieve the goal of "training 100 customers, introducing 200 projects and covering 300 engineers in the second half of 2023".

Figure4: Dr. Han Zhiyi, General Manager of SYNWIT

Dr. Han Zhiyi called on domestic manufacturers to work hard in the drive chip market together. He said: "We tend to define the screen as a mini smart phone, which can see, touch, listen and communicate. This is a very interesting industry. Its market is in China, its scheme is in China, its panel is in China, its LCM is in China, and its chip is also in China. By integrating Chinese resources together, we can make this market bigger and stronger and contribute to the industry. "

For R&D engineers, HYNWIT is constantly optimizing the product service ecology. To provide engineers with a more convenient and competitive development experience. Taking the development of screen drive MCU scheme as an example, SYNWIT has made four optimization measures to lower the development threshold of engineers.

- Process simplification

R&D engineers can complete development without touching the complex bottom layer, and do not need to learn the basic code. Just drag the control on the upper computer to achieve smooth display effect.

- Shorten the development cycle

In the development process, if the engineer does not need to modify the underlying development, it is expected that the preliminary debugging of the scheme can be completed in 1-2 weeks; If you need to modify the bottom layer, this cycle is expected to take 3-4 weeks.

- Provide exclusive compression algorithm

SYNWIT ui designer uses an exclusive compression algorithm to compress JPG, BMP, PNG and other pictures to one fifth of the original. 60-65 frames at 800*480 resolution and 25 frames at 1024*600 resolution.

- Application of master control function can be integrated

SWN34SRET6/SWM34SVET6, in addition to screen drive application, there are additional peripheral ports for control application.

In addition, SYNWIT also has a self-developed HMI host computer, namely Synwit UI Creator. According to the advantages and characteristics of SWM34S, it is designed and optimized to provide users with convenient, fast, WYSIWYG interface layout function and detailed style attribute control, and help users quickly build UI interface based on LVGL.

Figure5: Demonstration of SYNWIT HMI Upper Computer

After editing, the development engineer can view and verify the interactive effect of the interface on the computer through PC simulation. Engineers are freed from the time-consuming and labor-intensive interface layout work, which can effectively accelerate project development. At the same time, in order to facilitate customers' secondary application development, SYNWIT provides customers with reference applications, including schematic diagram, source program SDK and application description. In addition, it also provides application routines for electric vehicle dashboard, coffee machine, charging pile, 86 boxes and other related markets.

MCU has a wide range of applications and great market potential, which is an opportunity and a great test of ability for domestic MCU manufacturers. In the process of deepening the MCU field, SYNWIT is gradually improving its technology and market service ecology, making its products have advantages in cost and performance, becoming a better choice for more scheme designs and gaining the trust of the market.

Judging from the R&D path of SYNWIT and this conference, in recent years, SYNWIT has continuously upgraded the products and ecological services of iterative MCU in the fields of screen drive, motor control and general purpose, and cooperated with upstream and downstream partners to continuously develop this field, which has begun to take shape in the market. It can be predicted that domestic MCU manufacturers with R&D strength, such as SYNWIT, will continue to study deeply, build technical barriers, strive to stand out in the golden track of MCU, seize market opportunities, and eventually become the underlying products supported by more terminal equipment to meet the future of domestic chips.

The Market Demand Outlook is Positive, and Domestically Produced MCU are Ushering in a Golden Opportunity for Development-China.exportsemi.com