"Industry software development model is very important and industry simulation application value of software is important too. For example, in the large aircraft project, Boeing 777 first made computers simulation computer simulations of the aerodynamic behavior of large aircraft are used much of the time. Structural design, main force and lift, torque, AVH when aircraft vibrates to a certain extent, in fact, industrial simulation software is very important. "

Chen Shiyi, academician of Chinese Academy of Sciences and chief consultant of Shenzhen TENFONG Co., Ltd., pointed out that "China's independent industrial software is China science and technology strategic place to tackle key problems is the strongest boost for the continuous innovation and upgrading of China's manufacturing industry. Industrial simulation software must develop its own core technology and independent software. "

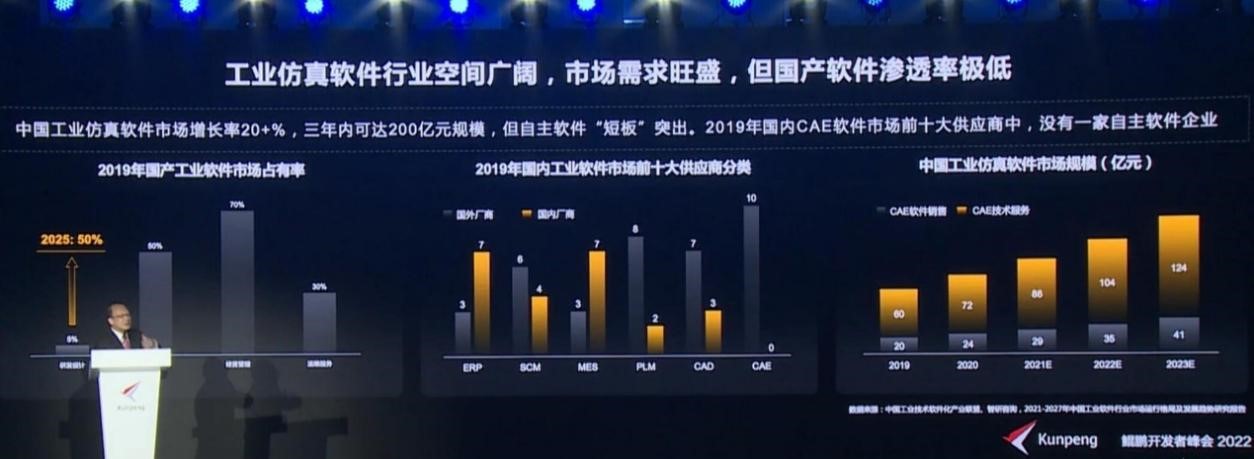

Academician Chen pointed out that according to the data of China Industrial Technology Software Industry Alliance, the growth rate of China's industrial simulation software market will be 20% in 2021, which can reach the market scale of 20 billion within three years, but the shortage of independent software is outstanding. In 2019, among the top ten suppliers of ACE (Computer Aided Engineering, a technical software widely used in the R&D and design process of industrial manufacturing products) software market in China, there is no independent software enterprise. At present, the penetration rate of domestic CAE is 11%.

Top five manufacturers and development trend of industrial software market

It is reported that in 2020, the global CAE market will be dominated by the top three suppliers, namely SIEMENS, ANSYS and DASSUALT, with a total market share of 47%. The other two of the top five CAE suppliers are ALTAIR and HEXAGON respectively. The localization rate of China's CAE market is less than 5%, and the main manufacturers are PERA China, ZW soft and ANWISE Technology. There is a big gap between domestic enterprises and foreign countries in technology.

Academician Chen believes that although there is a technological gap between China's industrial software enterprises and foreign enterprises at present, there is a lot of room to keep up with the pace of advanced manufacturers in the future. According to the author's research, international industrial software has entered the third stage of development, represented by foreign-funded enterprises SIEMENS, DASSAULT and ANSYS, which have realized the technical accumulation of software itself. And in the practice of national industrialization, the application collaboration of software is realized, and the process collusion and optimization are realized. These giants are upgrading to the overall solution of "Software + Service". However, China's industrial software industry is currently in the first stage. A large number of core industrial software such as design and manufacturing are occupied by foreign brands, and there are only a handful of Chinese enterprises, which can be summarized as "strong management software, weak industrial software, more low-end software and less high-end software". Manufacturing in China intelligence upgrade at present, Chinese industrial enterprises have a wide demand for software upgrade, giving domestic manufacturers sufficient room for development.

SIEMENS recently demonstrated the case of Nanjing's native digital factory. From planning and construction to operation and management, this factory relies on Siemens' native digital technology and concept, and supports the factory from scratch, turn virtual into real. The "digital twin" covers the whole product line and the complete life cycle of the factory, realizing digital closed loop. "We design factories and production lines like products. For example, before the actual ground breaking, Siemens has completed the construction of factories in the virtual world. Process Simulate simulates a single device and man-machine cooperation, robot work, refine the production unit, and integrate the data of each link in Teamcenter platform, which is convenient for members to share and cooperate. " The head of Siemens said that the new factory can produce at the same time electron and motor manufacture two categories of products that are quite different from raw materials, production equipment and process flow.

After putting into production, its production capacity will be nearly doubled, its production efficiency will be increased by 20%, its flexible Manufacturing will be increased by 30%, its time to market will be shortened by nearly 20%, its space utilization rate will be increased by 40%, and its logistics circulation efficiency will be increased by 50%.

It is reported that SIEMENS displayed its industry at the HANNOVER MESSE in Germany 5G dedicated network application case: an automatic guided vehicle (AGV) connected by 5G. When the AGV and mobile robots are applied to the internal logistics in the production process, the production flexibility can be effectively improved. Reliable wireless communication provide guarantee for its stable and safe operation. SIEMENS has realized the transmission of Profinet IO protocol through 5G private network, thus transmitting data in real time for industrial applications. This breakthrough was achieved by SIEMENS SCALANCE 5G router. The central controller can transmit Profinet through 5G private network, which can be carried out with distributed I/O modules on mobile devices such as automatic guided vehicles (AGV) communication it eliminates the need for local control of each individual mobile device, saving costs and reducing maintenance.

The road of China's industrial software development: domestic substitution points to substitution and iteration

China's industrial software industry is currently in the beginning stage. A large number of core industrial software such as design and manufacturing are occupied by foreign brands, and there are only a handful of Chinese enterprises, which can be summarized as "strong management software, weak industrial software, more low-end software and less high-end software". With the intelligent upgrading of China's manufacturing industry, China's industrial enterprises have a wide demand for software upgrading, giving domestic manufacturers sufficient room for development.

Academician Chen pointed out that the development of independent industrial simulation software currently faces three major challenges: First, the domestic market is almost monopolized by foreign manufacturers; Second, the industrial software industry needs compound talents, and there is a big talent gap in China at present. According to the "Key Software Talent Demand Report", by 2025, the gap of key software talents in China will reach 830,000, of which the gap of industrial software talents is 120,000; Third, the technology of domestic computing platform needs to be improved urgently.

Of course, Chinese industrial software enterprises also face three major opportunities. First of all, China's industrial structure is upgraded and police support Second, with the new scientific and technological revolution, China keeps pace with the world. Optimize the calculation speed and cost, integrate the simulation workflow, and improve the usability of products. Moreover, AI + big data will greatly shorten the solution time and improve the solution speed. IIoT + digital twinning makes it possible to build more complex simulation systems across processes and systems.

Recently, in 2022, HUAWEI developer, Zhang Xiwei, president of HUAWEI KUNPENG Computing Business, said that after three years of development, KUNPENG ecology has become increasingly prosperous. Up to now, the complete appliance partner shipments have accounted for more than 90%, Euler shipments have exceeded 1.7 million sets, and Gauss's community download the cumulative volume exceeded 800,000 times, and more than 4,000 partners solve more than 11,000 solutions together. KUNPENG has been applied in various industries on a large scale and has become the first choice for digital transformation of the industry.

In terms of enabling industrial manufacturing, last year, HUAWEI, together with BAODE, TALKWEB Information, YCTCO, APULIS Technology, Zhongke HONGYUN, HUARUI Technology, WORDOP, ADLINK Technology, ADVANTECH and DONGSHENG Intelligent, released the ASCEND intelligent manufacturing solution. In view of the pain points of manufacturing enterprises, such as low qualities inspection efficiency, poor flexibility and insufficient precision, ASCEND Solution is based on the mature practice of AI application in HUAWEI Southern Factory, creating AI quality inspection solution, and striving to accelerate AI scale to serve digital factories.

"In addition to traditional industrial design, industrial software is also a big one in the digital economy artificial intelligence develop with data collection. There is a long way to go to develop independent industrial software. In the next 5 to 10 years, we need talents and markets. Guangdong is very good, Huawei takes the lead, and many other enterprises are participating. The West has adopted a containment strategy against us. Now is the best time to develop independent industrial software. " Chen said.

Li Jingyan, founder and chairman of Beijing SHI GUAN JIN YANG Technology Development Co., Ltd., said that the domestic substitution of industrial software should be replacement and iteration. Benchmarking foreign excellent software is to benchmark its achievable functions, not the benchmarking software itself. Foreign software has a long history, which lay a solid foundation but also have problems. For example, GCKcontrol adopts new technology to solve the problem simulink the problem of slow speed in simulating large models. With the upgrading of intelligent manufacturing in China, China inevitably needs and should give birth to software giants comparable to DASSUALT and SIEMENS, or form a software ecology comparable to them.

Examining the Rise of Chinese Industrial Software through the Iterative Replacement of Domestic Industrial Simulation Software