Brain of TESLA: Insulated Gate Bipolar Teansintor

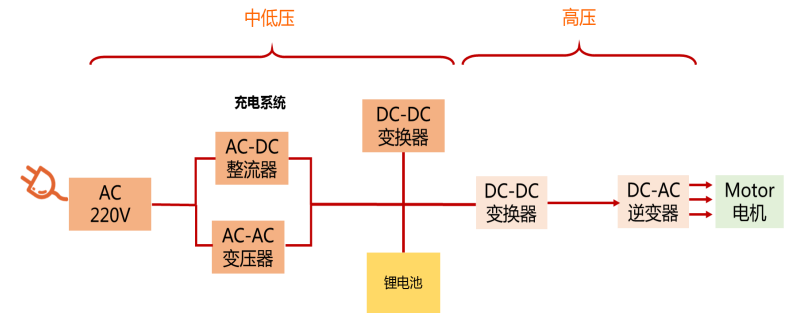

The structure of new energy vehicles will become very simple because they no longer need mechanical parts such as engines. The structure of vehicles is mainly composed of batteries, motors and electronic controls. The electronic system of new energy vehicles mainly includes battery management system, motor controller, on-board charger, converter, inverter, steering system, relay and passive components.

In practical application scenarios, because all modules of automobiles use alternating current, the input current of lithium battery is direct current, and the voltages of various electrical equipment are different, the corresponding power conversion system is needed. According to the different conversion sequences of DC and AC, power conversion can be divided into four modes: transformer (AC-AC), rectifier (AC-DC), converter (DC-DC) and inverter (DC-AC).

Power conversion process of TESLA

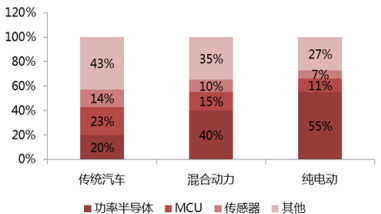

Automotive electronics occupies a very important position in automobiles. From the perspective of cost structure, it is more important for high-end automobiles and electric vehicles. From traditional vehicles to new energy vehicles, the biggest increase in value is power semiconductors. In traditional fuel vehicles, power semiconductors are mainly used in the fields of start-up, stop and safety, accounting for only 20%. According to traditional vehicles, the value of semiconductor bicycles is $350, and the value of power devices is $70. The battery power module of new energy vehicles needs a large number of power equipment, all of which contain power semiconductors. The power devices of hybrid vehicles account for 40%, and the power devices of pure electric vehicles account for 55%. According to the value of pure electric vehicles' semiconductors of 750 US dollars, the value of power semiconductors of 413 US dollars. The semiconductors used in new energy vehicles are 7 times that of traditional vehicles.

Proportion of automotive electronics of various models

In automotive applications, IGBT is mainly used in electric drive system, power supply system and charging pile in high voltage environment. The application range is generally in the withstand voltage above 600V, current above 10A and frequency above 1KHz.

- Electric drive system:Mainly used in inverter (DC-AC), which converts 12V DC electricity of rechargeable battery into 220V AC electricity of driving motor, is the core of motor driving. Dozens of IGBTs are needed in the motor control system, such as Tesla's three-phase AC asynchronous motor, which uses 28 IGBTs for each phase, totaling 84, 12 IGBTs for other motors, and Tesla uses 96 IGBTs in total.

- Power system:It is mainly used in car charger (AC-DC) and converter (DC-DC) to realize lithium battery charging and power supply conversion of required voltage level.

- All the electricity in the electrical grids is AC electricity,and the charging piles are classified into fast-charging DC charging piles and slow charging AC charging piles. IGBT is mainly used in DC fast-charging piles.

In 2018, the global automotive IGBT market capacity is 1.84 billion US dollars, and we expect the automotive IGBT market capacity to be 2.08 billion US dollars in 2020.

Automotive IGBT market space (US $100 million)

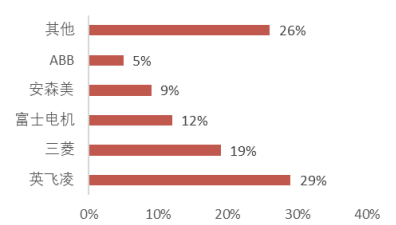

INFINEON, MITSUBISHI and FUJI Electric are in the leading position in the global IGBT market. ONSEMI (FAIRCHILD) is mainly concentrated in the low-voltage consumer electronics industry, with a voltage below 600V and a medium-high voltage above 1700V, which is mainly used in high-speed rail, automobiles, smart grids, etc., and is basically monopolized by INFINEON, ABB and MITSUBISHI.

Global IGBT competition situation

Eyes of TESLA: CIS Chip

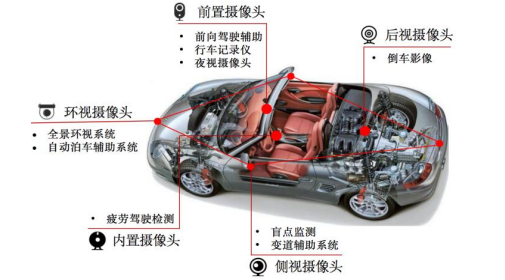

The visual system ADAS can recognition such as road signs, pedestrian and vehicle recognition, lane line sensing and so on by using cameras. High-end cars are equipped with various auxiliary devices, and they can have up to eight cameras used to assist drivers in parking or trigger emergency braking MCNEX company predicts that if cameras replace side mirrors in the future, there will probably be 12 cameras on cars. With the development of smart car technology and driverless technology, the demand for cameras for smart driving vehicles above L3 will increase.

TESLA Camera Chip Layout

CIS applications in vehicle field include: Rear View Camera (RVC), Omnidirectional View System (SVS), Camera Surveillance System (CMS), FV/MV, DMS/IMS. Rear-view camera (RVC) is large sales volume, showing a steady growth trend. The global sales volume was 51 million units in 2016, 60 million units in 2018 and is expected to reach 65 million units in 2019. At the same time, the global sales volume of FV/MV has grown rapidly, reaching 10 million units in 2016 and 30 million units in 2018. After that, it is expected that FV/MV will still maintain a rapid growth trend, with an estimated sales volume of 40 million units in 2019 and 75 million units in 2021, which is close to the global sales volume of RVC.

Sales volume of different CIS applications in vehicle field

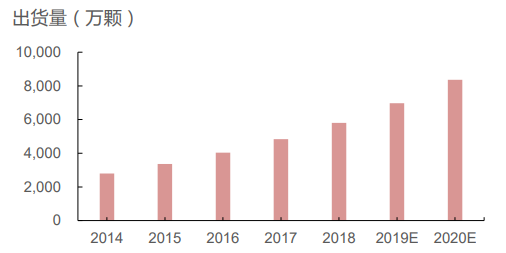

According to the forecast of CHNCI, the global shipments of car cameras are expected to increase from 28 million in 2014 to 82.7 million in 2020. Nowadays, most countries are formulating corresponding laws and regulations to force new cars to use some special ADAS technologies, while on-board cameras are widely used in automobile intelligence and will be the most used automobile sensors in the future.

Global shipments of car cameras

Memory

In Tesla's self-driving circuit board equipped with two FSD chips, the blue area in the figure is the memory particle used to store the operating system. Considering the automatic driving technology moving towards a higher level in the future, the memory particles carrying the deep learning model that can be continuously upgraded in the future have an obvious trend towards large capacity.

There are four green chips on both sides of the processor module, with a total of eight LPDDR4 running memory particles. The built-in LPDDR4 RAM memory module in FSD circuit board runs at a speed of 4,266 Gb per second, with a peak bandwidth of 68GB/s, so that the integrated image signal processor can perform operations up to 1 billion pixels per second.

Tesla equipped with the Full Self-Driving (FSD) chip's automatic driving circuit board

Display Panel of TESLA

TESLA is expected to drive the application trend of electronic components in new energy vehicles, including central control large screen (BOE A, TCL Group), automobile precision metal components, battery connector module (ANJIE Technology), central control display module (TOKEN Science), automobile LED headlights (SANAN Optoelectronics), etc. The average central control display screen of TESLA Model series products is 17 inches, which is higher than the average size of 7-8 inches of ordinary fuel vehicles, and is about 4 times of the average market application size area. The electronic application trend of automobiles will drive the area growth demand of LCD on-board screens.

Secondly, the car screen has strong customization characteristics, which is usually equipped with touch function. Compared with ordinary LCD standardized products, it has higher revenue and profit elasticity. At present, a-Si LCD products are still the main applications of vehicle screens, accounting for 90%, mainly due to higher product reliability and slower product iteration. LTPS LCD accounts for about 10%. LTPS has advantages in high integration and high resolution, and new energy/Internet car companies are more willing to use LTPS. With the production capacity of LTPS industry gradually shifting from mobile phone market to IT and vehicle market, the vehicle market share is expected to further increase in the future.

Tesla central control scene

According to TCL CSOT statistics, in 2019, the global shipment of vehicle screens was about 170 million pieces, which was calculated according to the average size of 7 inches, corresponding to the monthly production capacity demand of the 6th generation line of about 100K. The increase of vehicle-mounted screens, average size and number of single-vehicle applications will further rapidly drive the demand for LCD production capacity. At present, JDI, a Japanese company, is the leading shipper in the car screen market. Its car screen products are mainly instruments, and the shipments of a-Si/LTPS LCD rank first in the world, of which LTPS market accounts for about 70%.

ANJIE Technology entered the automotive electronic metal parts market by acquiring Singapore SEKSUN in 2014. In 2016, it successfully developed the new energy vehicle business and entered TESLA supply chain. At present, it has formed a large-scale supply in battery connector modules. In the future, with the improvement of the localization rate of parts in TESLA Shanghai factory and the shipment of new models such as Model Y, its revenue scale and supply material types are expected to further increase.

Touch display module of TOKEN Science business covers high-quality customers all over the world. At present, it has formed the leading position of touch module in the fields of automotive electronics, consumer electronics and wearable devices. In the field of new energy vehicles, the central control panel products of Model X/S models have been provided at present, while the central control products of Model3 and other models are in the process of product certification.

LENS Technology has cooperated with TESLA for more than one year and is a global first-class supplier. At present, the products include the assembly of central control products, including glass, touch control, bonding devices, and the assembly of the overall functional components of B-pillar modules. Continue to benefit from Tesla's shipment growth and the overall application trend of new energy vehicles.

Tesla B-pillar assembly

TESLA, as the flagship brand of new energy vehicles, comes standard with LED headlights, including high beam lights and low beam lights, which is expected to drive the continuous penetration of LED lamps into new energy vehicles and benefit SANAN Optoelectronics, a leading domestic LED manufacturer.

FPGA Chip, core of TESLA

Automotive semiconductors have a market size of 38.9 billion, and FPGA currently accounts for only 2.4%. The development of autonomous driving will increase the value ratio of FPGA and ASIC. Automobile main control chips include GPU, FPGA, ASIC, etc. FPGA is relatively mature in cameras and sensors at present, and will be widely used in ADAS/AD system, motor control, light detection and ranging, vehicle infotainment system and driver information system in the future. According to Bloomberg data, the market size of automotive semiconductors reached US $38.86 billion in 2017, of which FPGA was US $950 million, accounting for only 2.44%, and there is huge room for improvement.

Scale of automotive semiconductor market

Upstream foundry will benefit from the increased demand for downstream products. According to the company's state, SMIC and Hua Hong Semiconductor's automobile and industrial market revenue accounted for 4.8%/25% respectively in the third quarter of 2019. If downstream FPGA and ASIC pull goods due to new energy vehicles, it will contribute to the performance growth of foundry.

The overall silicon content of electric vehicles has increased, which is good for semiconductor equipment in the industrial support link

Automobiles, especially electric vehicles, are gradually evolving from a mechanical product to an electronic product, and their core capabilities are no longer engines or chassis and power transmission systems, but chips and software. The silicon content of electronic devices of electric vehicles is constantly increasing, which is beneficial to semiconductor equipment in the supporting link of the industry.

5G + AIOT + automotive electronics drive global semiconductor equipment into a new upward cycle. Mainland China has undertaken the center of semiconductor manufacturing capacity, and the global market share of equipment in Mainland China continues to rise, with the expectation of reaching the world's first in 2021. Since Q2, 2019, the mainland's independent fab has entered the peak period of production, and the demand for semiconductor equipment will usher in explosive growth in the next three years. According to the statistics of the start-up and production of independent fab in mainland China from 2017 to now, it is estimated that the cumulative total investment of semiconductor equipment in the next 19-22 years will be about 70 billion US dollars, which has great room for growth compared with 12 billion US dollars in 2018. The expansion of fab itself has the procurement demand of cost reduction, which is conducive to the improvement of localization rate. In 2018, the localization rate is less than 15%, and there is huge room for improvement.