With the rapid development of science and technology, the semiconductor industry is facing increasing market demand and technical challenges. In this context, the automation of semiconductor test processes has become one of the important factors driving modern production. This article focuses on the key role of automated testing in improving production efficiency, reducing costs, and enhancing product quality.

Improve testing efficiency

Traditional semiconductor testing is often manual, inefficient, and error-prone. Automated test equipment, on the other hand, can perform a large number of test tasks quickly and accurately, significantly shortening the test cycle. Modern test systems improve overall production efficiency through parallel processing and high-speed testing technology, which enables the quality inspection of products in the shortest possible time.

Reduce labor costs

Manual testing is not only time-consuming, but also labor-intensive. By introducing automated testing systems, businesses can reduce their reliance on human resources, thereby reducing operational costs. In addition, the use of automated equipment reduces the occurrence of human error and ensures the reliability of test results.

Enhance test accuracy

The automated test system uses consistent testing procedures and standardized operations to significantly improve the accuracy of testing. A high degree of consistency is maintained in every test, thus ensuring the quality of the final product. This is especially important for semiconductors that require extreme precision.

Real-time data analysis

Modern automated test systems have powerful data collection and analysis capabilities. Data monitored in real-time during testing can be quickly fed back to the production team, helping them identify and resolve potential issues in a timely manner. This fast response capability not only increases the flexibility of production, but also reduces the failure rate.

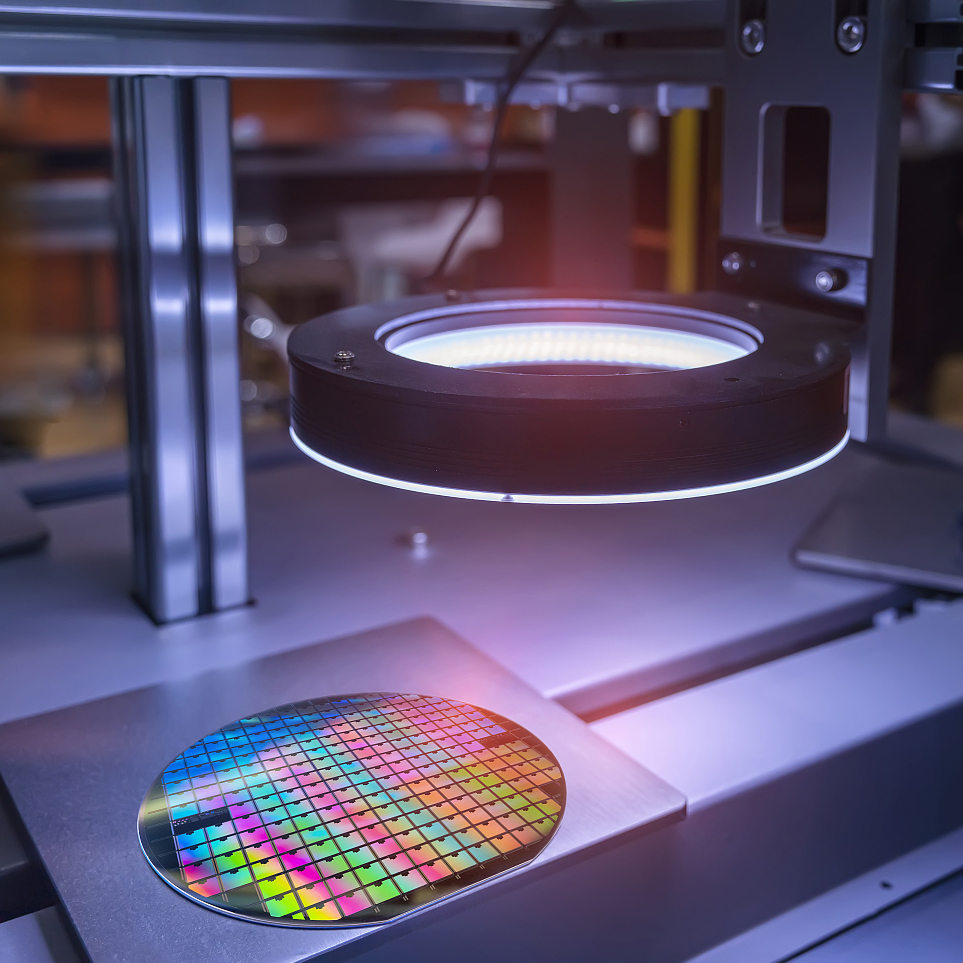

Figure: Semiconductor test automation is the key to modern production

Adaptable to complex products

As semiconductor technology continues to evolve, chip designs are becoming more complex. The automated test system can flexibly respond to the testing needs of various new products and adapt to diverse market challenges. With software updates and hardware improvements, automation equipment can be quickly adapted to support the testing of new products.

Traceability and compliance

In the semiconductor manufacturing process, it is critical to ensure that products meet industry standards and regulatory requirements. The automated testing system can provide detailed test records to ensure the traceability of each product. This not only increases customer trust, but also streamlines the compliance process and helps companies meet regulatory requirements.

Support smart manufacturing

Combined with artificial intelligence and machine learning, automated test systems are self-learning and optimizing, further driving the development of smart manufacturing. By analyzing historical test data, the system is able to identify the best testing strategy to improve productivity and product quality.

The semiconductor industry is growing rapidly, with new products and technologies constantly emerging. To remain competitive, automated test systems must be highly flexible to adapt to rapidly changing designs and processes. However, existing automation systems sometimes lack sufficient scalability and adaptability to quickly respond to new technologies or design changes. This results in test equipment requiring frequent updates or refactoring, increasing maintenance costs and complexity.

While there may be various challenges associated with automated semiconductor testing, the automation of the semiconductor testing process is an indispensable part of modern production. By improving test efficiency, reducing costs, enhancing test accuracy, and supporting smart manufacturing, automated testing provides strong support for the sustainable development of the semiconductor industry. In the future, with the further development of technology, the application of automated testing will be more extensive, promoting the transformation and progress of the entire semiconductor industry.