eBeam Infrared recently completed its 13th annual Luminaries Survey, which surveyed 49 companies from across the semiconductor ecosystem, including industry leaders in reticles, electronic design automation, chip design, devices, materials, and research. The eBeam Initiative is an industry organization that provides a forum to educate and promote new approaches to semiconductor manufacturing based on electron beam (eBeam) technology. These methods can help reduce the cost of reticles for semiconductor devices based on electron beam technology. Founded in early 2009, the eBeam Initiative quickly established itself as a powerful collaborative forum for the semiconductor manufacturing community.

According to the survey results, 100% of respondents predict that mask revenue in 2024 will increase (74%) or remain unchanged (26%) compared to 2023. Respondents are also positive about equipment purchases over the next three years, with multibeam reticle writing devices (93%), reticle inspection (85%) and laser reticle writing devices (48%) expected to increase. In addition, the percentage of industry leaders who believe that fabs without EUV can reach 5nm in 7 years increased from 12% last year to 19% this year.

With the continuous scaling of semiconductor process nodes, EUV technology is widely used in advanced processes, especially in 5nm and below. The high resolution of EUV technology enables pattern etching by several nanometers, which is driving a significant increase in the demand for high-precision EUV masks.

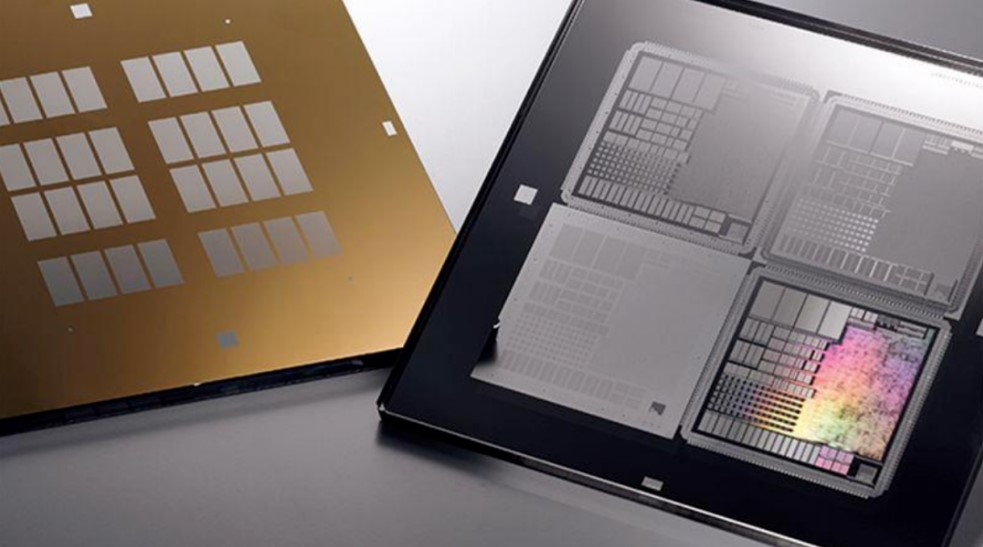

Figure: EUV is driving the growth of the photomask market

Photomasks, also known as photomasks, are graphic masters used in the photolithography process in microelectronics manufacturing to precisely transfer circuit designs onto wafers or substrates. It is a key material in the manufacturing process of industries such as semiconductors, flat panel displays, touch panels, and circuit boards. With the advancement of technology and the drive of market demand, the global photomask market size continues to expand.

This year's survey also added questions about EUV reticles and high-NA splicing. 81% of respondents believe that stitching for high-NA EUV reticles will require designers to pay attention to stitching boundaries during the design process. Thirty-three percent of respondents believe that EUV reticles that use reticles last at least three times longer than those who do not use reticles. In the semiconductor field, photomasks account for about 60% of the market share, while the LCD field accounts for about 23%. With the transformation and upgrading of the electronic information industry, high-end mask plates occupy a favorable position in the market competition.

The future of masks will be influenced by a variety of factors. With the increasing requirements for product accuracy and resolution in the fields of display panels and semiconductors, the demand for high-precision masks is also increasing. At the same time, the growth of emerging application areas, such as OLED displays and flexible electronics, is also an important factor driving the development of the mask industry. It is estimated that by 2028, the size of China's mask market will reach 36 billion yuan.

In addition to semiconductor manufacturing, masks are used to transfer circuit patterns to glass substrates in the field of flat panel displays, enabling the manufacture of display driver circuits. With the continuous innovation of display technology, the performance and accuracy requirements for masks are also increasing. The flat panel display mask market size is also quite impressive, accounting for 23% of the overall photomask market. The manufacturing process of photomasks is complex, involving multiple steps such as lithography, development, etching, decoating, and cleaning. With the advancement of technology and the development of downstream application fields, the accuracy and performance requirements of masks are also increasing. The global photomask market is growing steadily, and the Chinese market occupies an important position in it, and there is huge room for domestic substitution.