REC Silicon has signed a long-term silane supply agreement with Sila, marking a significant step in the collaboration between the two companies in the supply of silicon materials. REC Silicon is the world's leading manufacturer of high-purity silanes, specializing in the production of solar-grade polysilicon, electronic-grade polysilicon and silane gases. Sila, on the other hand, is a company dedicated to developing the next generation of battery materials, and its product, Titan Silicon, is designed to improve battery performance in electric vehicles and consumer devices.

Silane (SiH4) plays a vital role in the semiconductor industry, and it is a key material for the manufacture of high-purity polysilicon, monocrystalline silicon, microcrystalline silicon, amorphous silicon, silicon nitride and many other metal silicides. Due to their high purity and ability to achieve fine control, silanes have become an important electronic specialty gas that cannot be replaced by many other silicon sources.

In semiconductor manufacturing, silanes are mainly used in chemical vapor deposition (CVD) and plasma-enhanced chemical vapor deposition (PECVD) processes, which are used to deposit various thin films on the surface of silicon wafers, such as silicon dioxide (SiO2), silicon nitride (SiNx), etc. These films are used in the manufacture of integrated circuits to form insulating layers, conductive layers, protective layers, etc. The high purity of silanes is critical to the performance and reliability of semiconductor devices, as any tiny impurity can lead to degraded performance or failure.

In addition, silanes are also used to make solar cells, optical fibers and photoelectric sensors. With the development of technology, the application fields of silane continue to expand, including the application of new energy batteries and other emerging fields. The purity and quality of silanes has a direct impact on the performance of these applications.

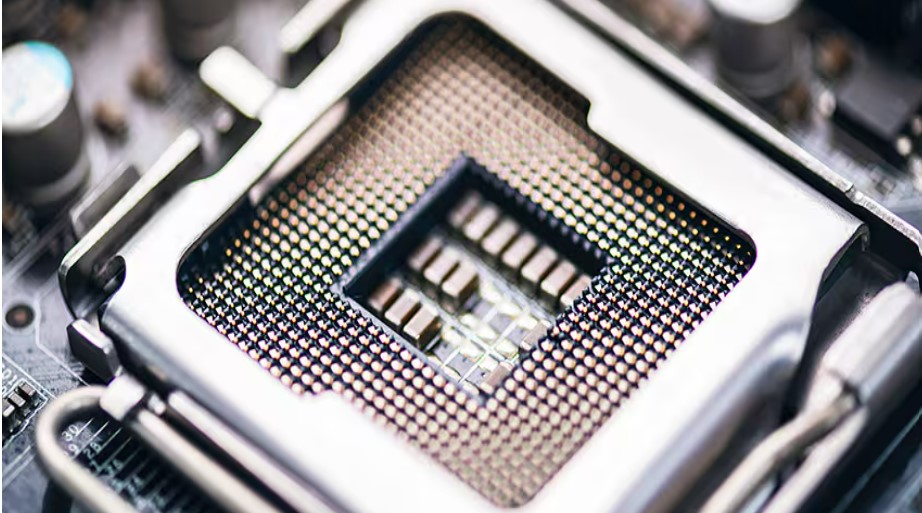

Figure: REC Silicon signs long-term silane supply agreement with Sila

In the semiconductor industry, the safety and handling requirements of silane are very high because it is a flammable and explosive gas that requires operation under strict safety measures. With the growing global demand for high-performance semiconductor devices, the market demand for silanes is also expanding, driving the development and innovation of related production technologies.

This cooperation is beneficial to both parties. For REC Silicon, the long-term supply agreement with Sila ensures market demand for its products and a steady stream of revenue. For Sila, REC Silicon's high-purity silane gas is a key ingredient for the production of high-performance battery materials, and this collaboration helps ensure the stability and quality of its material supply.

In addition, the collaboration has the potential to have a positive impact on the entire silicon material supply chain. As the market for electric vehicles and renewable energy continues to grow, so does the demand for high-performance silicon materials. The collaboration between REC Silicon and Sila will help advance silicon technology and improve supply chain efficiency to support these fast-growing industries.

Notably, REC Silicon's silane production facility has also made significant progress in terms of technological innovation and capacity expansion, with the first products expected to be delivered to the market from the second quarter of 2024. This shows that REC Silicon is actively expanding its production capacity to meet the growing market demand.

Overall, REC Silicon's collaboration with Sila is an important development in the silicon materials industry, which not only strengthens the positions of both companies in the market, but also supports stability and technological innovation throughout the supply chain. As the collaboration deepens, we can expect to see more applications of high-performance silicon materials in the future, especially in the fields of electric vehicles and renewable energy.