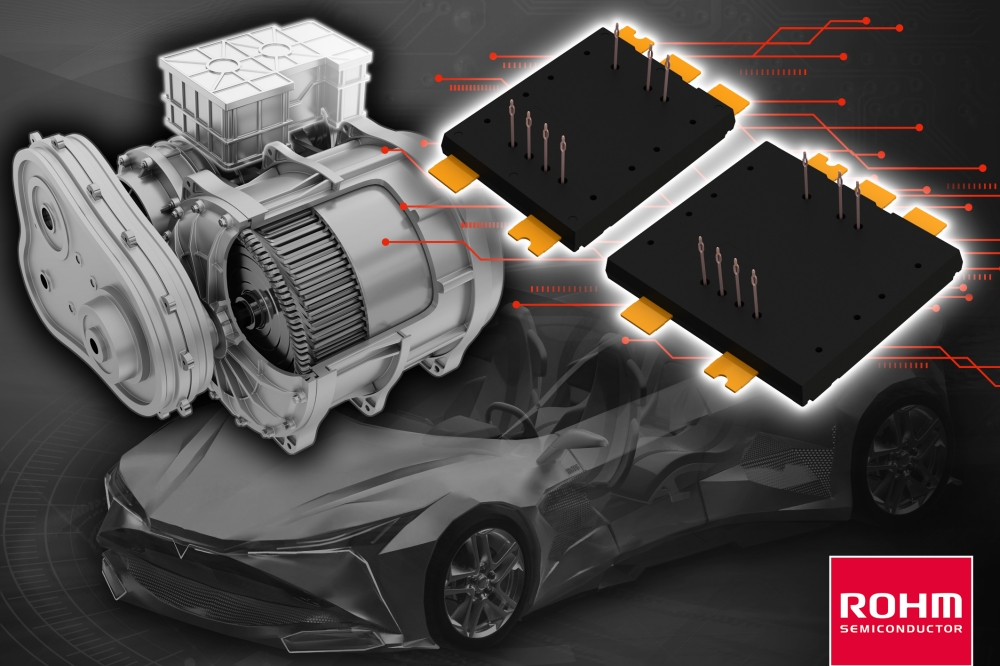

ROHM has reportedly succeeded in developing a 2-in-1 SiC module specifically designed for traction inverters for electric vehicles, an innovative technology that is expected to boost the performance and market adoption of electric vehicles.

ROHM's TRCDRIVE pack™ series of 2-in-1 SiC modules consists of two voltage ratings: 750V and 1,200V. Not only do these modules support up to 300kW of power, but they also address the challenges of traction inverters in terms of miniaturization, efficiency improvement, and man-hour reduction through a unique terminal configuration and high power density design. The products are mainly used in high-voltage and high-capacity development applications such as electric vehicles, data centers, base stations and smart grids to improve power conversion efficiency and convenience.

Technological advantages

High power density: ROHM's fourth-generation SiC MOSFET technology achieves an industry-leading power density that is 1.5 times higher than that of general SiC modules, greatly contributing to the miniaturization of xEV inverters.

Low on-resistance: Built-in low-on-resistance SiC MOSFETs help reduce power losses and improve system efficiency.

Simplified installation: The control signal terminal design with press-fit pins simplifies the connection process of the door drive board and significantly reduces the installation time.

Low-inductance design: A low inductance of 5.7nH is achieved by optimizing the current path and adopting a double-layer bus structure, which helps to reduce losses during switching.

Figure: ROHM launches a 2-in-1 SiC module

In recent years, the electrification of automobiles has developed rapidly in the pursuit of a carbon-free society, which has led to the development of more efficient, smaller, and lighter electric powertrain systems. On the other hand, SiC power devices, which are attracting attention as key devices, face the problem of reducing size and loss at the same time. In response to this, ROHM has developed the TRCDRIVE pack™, which can solve this problem in the powertrain.

In addition, ROHM's own structure has been adopted to maximize the heat dissipation area and realize a compact package.

ROHM has built a large-scale production system similar to discrete products, with a 30-fold increase in production capacity compared to traditional SiC modules. In addition, ROHM plans to launch 12 modules in different sizes and mounting modes by March 2025 to meet diverse design needs.

ROHM also provides comprehensive technical support, including application-level support using in-house motor test equipment, as well as ancillary materials such as simulation and thermal design to help customers quickly evaluate and adopt TRCDRIVE pack products. At the same time, ROHM offers two evaluation kits for two-pulse testing and three-phase full-bridge applications, ensuring effective evaluation in real-world inverter circuits.

As the global demand for xEVs continues to grow, ROHM's 2-in-1 SiC modules are expected to be one of the key technologies to drive the performance of electric vehicles. Such modules will not only help improve the range and dynamic performance of electric vehicles, but will also contribute to technological advancement and cost-effectiveness across the industry.