In the context of increasingly fierce global scientific and technological competition, semiconductor technology is gradually becoming the core indicator to measure a country's scientific and technological strength. China, as one of the world's largest semiconductor markets, is making every effort to promote the localization of semiconductor technology to enhance its strategic position in the global technology map. On July 19, 2024, at the theme salon on the high-quality development of the new energy automotive electronics industry held in Pingshan New Energy Automobile Industrial Park, Shenzhen, Chen Lu, editor-in-chief of China Exportsemi, participate the keynote speech by Mr. Yu Lei, sales director of Chengdu Rongsi Semiconductor. Mr. Yu Lei's speech focused on the application status and future prospects of silicon carbide (SiC) devices in the field of photovoltaic new energy and new energy vehicles, and deeply analyzed the opportunities and challenges in this key field in China.

Silicon carbide devices: star materials in the field of new energy

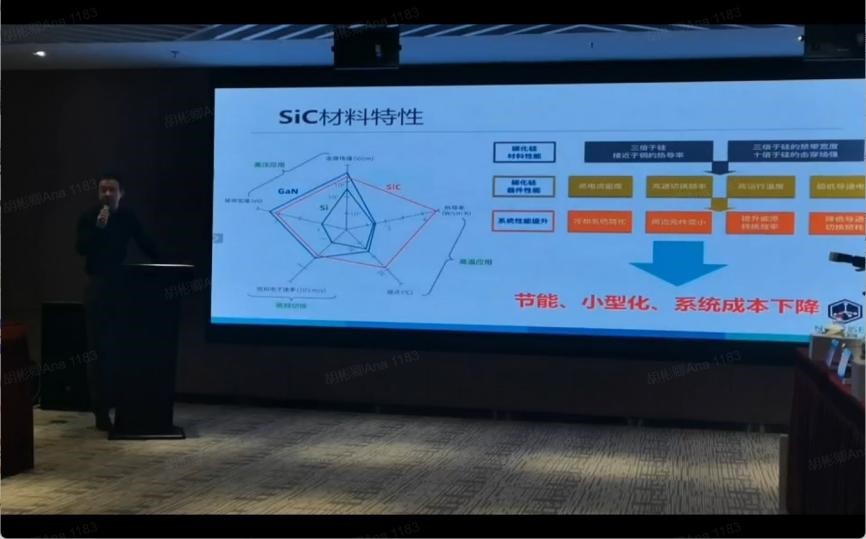

Silicon carbide (SiC), as a third-generation semiconductor material, has attracted widespread attention around the world in recent years. Compared with traditional silicon materials, silicon carbide has higher electron mobility, stronger thermal conductivity, and excellent performance at high temperatures and high frequencies. These characteristics enable silicon carbide devices to maintain excellent stability and efficiency in more harsh working environments, especially in new energy fields such as new energy vehicles and photovoltaic systems.

Mr. Yu Lei elaborated on the technical advantages of silicon carbide devices in the field of new energy. He pointed out that the electron mobility of silicon carbide devices is three times that of traditional silicon materials, and its thermal conductivity is far higher than that of traditional silicon materials, allowing it to maintain efficient and stable operation in high-temperature environments. In addition, the ability of SiC devices to operate at higher frequencies provides a solid foundation for their use in high-efficiency power conversion systems. These advantages make silicon carbide devices show great application potential in key fields such as electric drive systems and photovoltaic inverters for new energy vehicles.

Figure: Keynote speech by Mr. Yu Lei, Sales Director of Chengdu Rongsi Semiconductor: Application status and future prospects of silicon carbide (SiC) devices in the field of photovoltaic new energy and new energy vehicles

The new energy vehicle market is booming

China's new energy vehicle market is experiencing unprecedented rapid growth. According to statistics from the China Association of Automobile Manufacturers, China's new energy vehicle sales are expected to exceed 5 million units in 2023, and behind this staggering figure is the urgent need for high-performance semiconductor devices. In his speech, Mr. Yu Lei mentioned that the application of silicon carbide devices can significantly improve the performance of electric vehicles, especially in electric drive systems, which can greatly improve the energy efficiency and endurance of vehicles.

The introduction of silicon carbide devices can also significantly reduce power losses. Mr. Yu Lei gave an example that the traditional IGBT module has a large switching loss in the electric drive system, while the switching loss of silicon carbide devices can be reduced by 75%. This results in an overall energy efficiency increase of about 3% for new energy vehicles, with a maximum efficiency of 99%. In addition, the electric drive system of new energy vehicles using silicon carbide devices can increase the cruising range by about 10% under the same conditions, which is of great significance for improving the market competitiveness of electric vehicles.

The pursuit of high efficiency in the photovoltaic industry

The photovoltaic industry is another important application area for silicon carbide devices. With the increasing global demand for clean energy, photovoltaic power generation has become a key means for many countries to achieve energy transition. The core of the photovoltaic system lies in the efficiency and reliability of its power devices, and the high efficiency and high reliability of silicon carbide devices are the biggest advantages of its application in photovoltaic inverters.

Mr. Yu Lei emphasized that the power devices in the photovoltaic system need to work continuously 24 hours a day, which is more demanding than the working conditions of the devices in new energy vehicles. Therefore, photovoltaic systems have higher requirements for the reliability of power devices. Silicon carbide devices can significantly improve the conversion efficiency of the system in the photovoltaic inverter, reduce energy consumption, and ultimately achieve the goal of low cost and high efficiency of photovoltaic power generation. According to market data, the use of silicon carbide devices in photovoltaic systems reduces the energy loss of the overall system by more than 50%, while the volume of magnetic components is reduced by 70%, bringing significant technological progress to the photovoltaic industry.

Continued: Rong Si Yu Lei: The Domestic Production of Silicon Carbide Still Faces Many Challenges 2