As a leading large-scale LCD company in Taiwan, Innolux is actively transforming into the field of semiconductor packaging, and its panel substrate technology has attracted much attention. The company plans to mass production of semiconductor panel substrates by the end of 2024, and the application of this technology to the semiconductor cutting-edge packaging process is expected to significantly improve production efficiency compared to conventional round substrates.

According to Innolux's official disclosure, after years of R&D and technological innovation, the company has made a significant breakthrough in semiconductor panel substrate technology, which not only improves the performance and quality of substrate materials, but also optimizes the production process, laying a solid foundation for mass production. The implementation of this mass production plan marks an important step forward for Innolux in the field of semiconductor panel substrates, which will further enhance the company's competitiveness in the global display panel market.

As an important part of the display panel, the importance of the semiconductor panel substrate is self-evident. With the continuous development of display technology and the increasing market demand, the requirements for substrate materials are getting higher and higher. Innolux's mass-produced semiconductor panel substrates use advanced material science and precision manufacturing technology to significantly improve the clarity, color saturation and service life of display panels, bringing consumers a more superior visual experience.

Innolux has already converted its old LCD factory in Tainan to semiconductor packaging and uses a rectangular panel substrate as the basis for the rewiring layer, an innovative move that will help the company expand in the semiconductor packaging market. Innolux will use a 700 mm square metal substrate and a 620 mm ×750 mm glass substrate, which is nearly seven times the size of a traditional round substrate, which means that more chips can be processed at once.

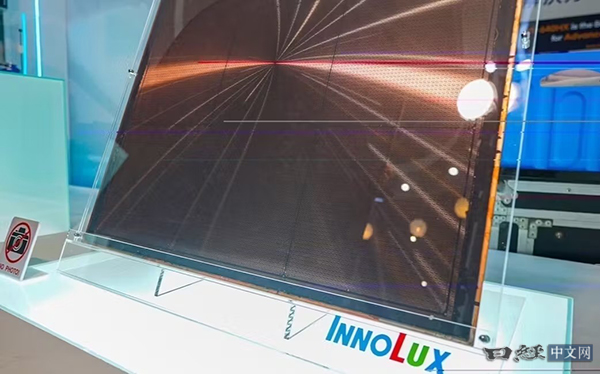

Figure: Semiconductor panel substrate technology is attracting attention, Innolux is expected to be mass-produced this year (Source: Innolux)

Innolux's transformation is expected to attract customers in high-end applications, including satellites and automotive. According to media reports, Netherlands semiconductor giant NXP Semiconductors is expected to become its first customer. Innolux will initially have a production capacity of 1,000 sheets per month, and plans to increase the production capacity to 3,000 to 4,500 sheets in 2024, with plans to further expand to 15,000 sheets in the future.

In addition, Innolux has made significant achievements in panel-level fan-out packaging (FOPLP) technology, which can effectively reduce costs and improve efficiency. Innolux's FOPLP technology utilizes the industry's largest G3.5 FOPLP glass substrate to develop mid- to high-end semiconductor packages that are seven times the size of a 300mm glass wafer. Innolux has invested about NT$2 billion in capital expenditure on this technology, which is a relatively small investment compared to the past capital expenditure of panel manufacturers in the panel industry.

With the rapid development of 5G, AI, IoT and other technologies, the application fields of semiconductor display panels are constantly expanding, from smart phones, tablet computers to smart homes, automotive electronics and other fields, all of which put forward higher requirements for high-quality and high-performance display panels. Innolux's mass production plan will help meet these market needs and promote the upgrading and transformation of the entire industry chain.

In addition, Innolux's mass production plan will also have a positive impact on upstream and downstream enterprises. With the improvement of the production capacity of substrate materials, it will drive the development of related equipment and raw material suppliers and promote the coordinated development of the entire industrial chain. At the same time, the high-quality substrate materials will also attract more cooperation from display panel manufacturers and further strengthen Innolux's leading position in the industry.