Tanaka Precious Metals Industries Group, one of the core companies of Japan's TAMAKA Precious Metals Group, recently announced that it has successfully developed the world's first massive high-purity platinum with a grain size of nanometers. This breakthrough technological innovation opens up a new path for the improvement of the performance of platinum materials, and has a wide range of industrial application prospects.

A breakthrough in nanocrystalline technology

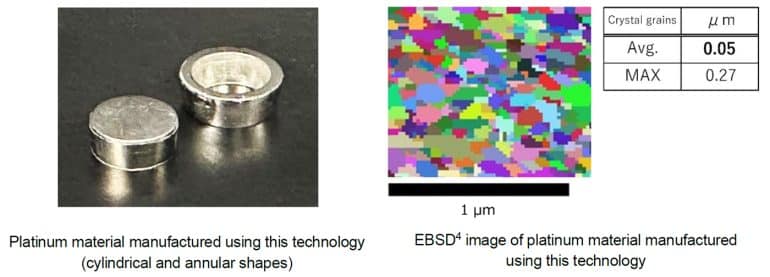

While the grain size of conventional metal materials is usually as small as 10 microns, the newly developed nanoscale grain platinum greatly optimizes the material properties by precisely controlling the grain size down to the nanometer scale. This new platinum material, which has a purity of 99.9% or more, has a 10-fold increase in hardness and a 4-fold increase in strength, far exceeding the physical properties of ordinary platinum materials.

Technological innovation and breakthrough of problems

In metallic materials, grain refinement is the key to enhancing material properties. However, most of the previous grain refinement methods rely on plastic deformation treatment and recrystallization technology, which has extremely limited effect on high-purity precious metals. In the traditional process, the crystal structure of precious metals is prone to changes in atomic arrangement in a short period of time, resulting in the rapid formation of new grains and the subsequent reduction of hardness.

TAMAKA overcame this technical bottleneck by optimizing the manufacturing process and successfully produced high-purity platinum blocks with stable grain structure and controlled dimensions. Studies have shown that this platinum material is rich in lattice defects such as small-angle grain boundaries, large-angle grain boundaries and dislocations, and still exhibits significantly better mechanical properties than traditional platinum materials even without the addition of other elements or alloying.

Image: TAMAKA successfully develops the world's first high-purity platinum material with nanocrystalline grain size (Source: SemiconductorDigest)

Broad industrial application prospects

Due to the good processability of this new high-purity, high-performance platinum material, this new material is expected to be used in a very wide range of industries. Good processability can reduce costs in the manufacturing process and improve production efficiency. For example:

Electronics industry: used in the manufacture of high-precision electronic components;

Aerospace: manufacturing of critical components for extreme environments;

Other high-tech industries, such as catalysts, sensors and precision instruments.

In addition, nanocrystals also play an integral role in the semiconductor industry, and the quantum size effect is significantly enhanced when the size of semiconductor materials is reduced to the nanoscale. This effect causes the electron energy levels to become discrete, which affects the conductivity and optical properties of the material. For example, the band gap of nanocrystals can be adjusted by controlling their size, which opens up the possibility of developing new electronic and optoelectronic devices. Nanosemiconductor materials typically have higher photoelectric conversion efficiency and better electrical conductivity. This makes them excellent in applications such as solar cells, LEDs, lasers, and sensors. For example, the use of nano-semiconductor particles can be used to create high-efficiency solar cells that can work even in rainy weather.

TANAKA's new technology not only demonstrates its innovative ability in the field of precious metal materials, but also provides a new material option with excellent performance for related industries. With the promotion of this nanocrystalline platinum material, it is expected to have a far-reaching impact on the development of high-end industries such as electronics and aerospace.

This technological breakthrough once again demonstrates the important role of advanced materials science in driving industrial upgrading and technological innovation, while reinforcing TANAKA's position as a technology leader in the field of precious metals.