The CPU manufacturing process, also known as the CPU manufacturing process, is an extremely complex and sophisticated collection of technologies in the process of manufacturing CPUs. It determines the performance of the CPU and is the top priority in the CPU development blueprint. It's not just about the density of integrated circuits, it's also about power consumption and computing power. This article will delve into the core concepts of the CPU manufacturing process and how they are evolving.

1. Overview of CPU manufacturing process

The CPU manufacturing process involves the delicate integration of complex circuitry and electronic components onto a single piece of silicon. The level of detail of this process is usually expressed in nanometers (nm), with smaller values indicating more advanced processes. Advanced manufacturing techniques can integrate more transistors on the same size of silicon wafer, significantly improving the performance and efficiency of processors.

2. the core elements of the CPU manufacturing process

Silicon wafer size: Silicon wafers are the building blocks for making CPUs. Larger wafer diameters can increase the number of chips in a single production and reduce unit costs. However, as wafer sizes increase, there is also a risk of yield loss.

Feature size: This refers to the minimum structure size that the manufacturing equipment can process on a silicon wafer, and is an important indicator of the level of the manufacturing process. Smaller feature sizes mean more efficient chip layouts, helping to improve performance and reduce energy consumption.

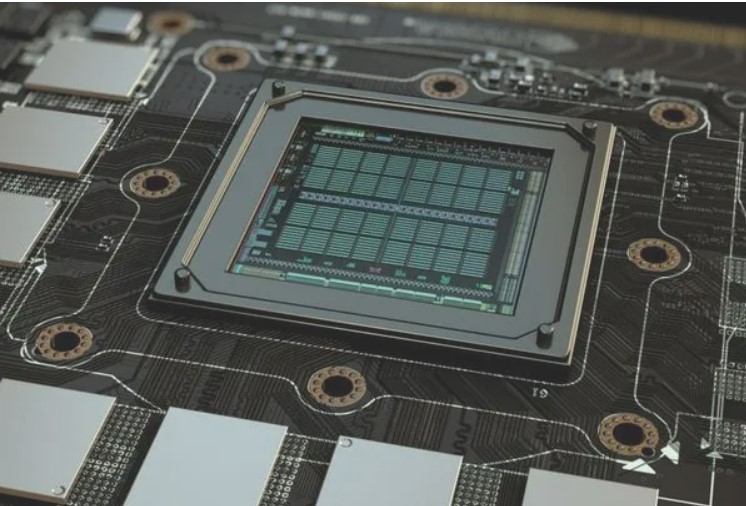

Figure: CPU manufacturing process

3. CPU manufacturing process

The manufacturing of a CPU is a complex process that mainly includes the following key steps:

Raw material purification: Silicon is extracted from ordinary sand and purified to electronic grade silicon through a series of chemical reactions.

Silicon wafer fabrication: Purified silicon is smelted into rods and then cut into thin slices to form wafers.

Wafer processing: Circuit patterns are created on the surface of the wafer through polishing, lithography, etching, and other steps.

Transistor construction and interconnect: Ion implantation techniques are used to alter the conductivity of silicon and deposit metal layers to enable connections between transistors.

Wafer Test & Segmentation: Perform functional tests on the entire wafer to ensure that each chip meets the standard before segmentation.

Packaging & Final Testing: Chips are packaged into finished CPUs and thoroughly tested to ensure reliability and performance.

4. the future trend of CPU manufacturing process

Ultra-miniaturization: As technology evolves, feature sizes will continue to shrink, allowing for the integration of more transistors to further improve CPU performance.

High-density integration: Advanced manufacturing techniques will enable CPUs to integrate more logic gates on the same area, increasing computational density.

Low-power design: A finer manufacturing process will help reduce the thermal design power (TDP) of the CPU, enabling higher frequencies.

Heterogeneous integration: Future CPUs will focus more on the design of heterogeneous architectures, integrating components such as GPUs, FPGAs, and AI accelerators to achieve more efficient task processing.

Customized solutions: In order to meet the needs of specific applications, CPUs will tend to be highly customized.

In conclusion, the CPU manufacturing process is essential to advance computing technology. As technology advances, we can expect more efficient, energy-efficient, and innovative processor designs.