After a brief understanding of ultrasonic radar and millimeter-wave radar, this article will focus on lidar. LiDAR is an advanced detection method that integrates three technologies: laser, global positioning system and inertial measurement equipment. It is an active remote sensing device that emits a laser and receives the echo reflected from the object, and converts the echo into a photoelectric signal to detect the physical parameters of the measured object, such as distance, azimuth, altitude, and speed.

Lidar: In the early stage of technology drive, the front loading is about to be put on the car

In recent years, the global lidar market has been expanding. According to reports, the global lidar solution market will reach 12 billion yuan in 2022, with an average annual compound growth rate of 63% in the past five years. It is estimated that by 2029, the total size of the global 3D lidar market will reach 52.743 billion yuan, with a compound annual growth rate of 63.58%. China's lidar market is also showing a rapid growth trend. In 2022, the size of China's lidar market will be about 2.64 billion yuan, and with the continuous innovation of technology and the continuous growth of market demand, it is expected that China's lidar market will continue to maintain rapid growth in the next few years.

LiDAR can classify components according to the wavelength of the light source, the transmitting system, the receiving system and the scanning system. According to the number of scanned moving parts, it can be divided into mechanical, mixed solid-state and solid-state lidar; According to the different ranging principles, it can be divided into ToF lidar (by measuring the time difference between the emitted laser and the echo signal to obtain the distance information of the target object, which has the advantages of fast response speed and high detection accuracy) and FMCW lidar (through the frequency difference obtained by the echo signal and the reference light coherently, the flight time is indirectly obtained and the target distance is launched, which has the advantage of directly measuring the speed information and strong anti-interference).

Figure: Classification of lidar

Automotive and OEM requirements

To achieve pre-assembly and mass production, the product needs to go through the product iteration and production verification process, and the whole process takes about 18-36 months. LiDAR automotive specifications and OEM requirements are two closely related aspects, which together drive the application and development of LiDAR in the automotive industry. Lidar manufacturers are limited to the performance and cost requirements put forward by OEMs, and the overall requirements are high perception performance, low cost, and high integration.

Domestic manufacturers have made remarkable progress in technological innovation. For example, Visionox's ViP AMOLED technology has the characteristics of FMM-free, independent pixels, and high accuracy, which can improve the resolution, display effect, and production yield of AMOLED displays. At the same time, Visionox has covered a number of technical fields in the layout of ViP technology, with a total of more than 500 patents, forming a number of independent intellectual property technology portfolios. Other manufacturers such as BOE and TCL Huaxing are also increasing investment in technology research and development, and enhance product competitiveness through the construction of high-generation production lines and the application of new technologies.

Upstream components are mature to reduce costs, and domestic penetration is expected to accelerate

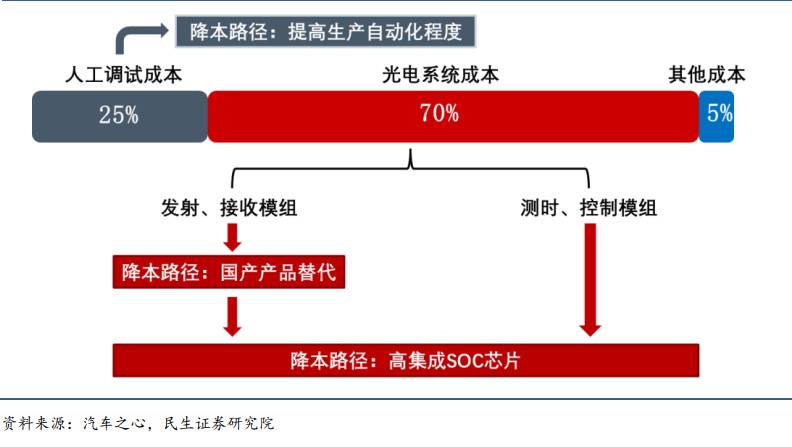

The cost of lidar is composed of the cost of the optoelectronic system (70%), the cost of manual debugging (25%), and the cost of other costs (5%), of which the optoelectronic system also includes modules such as transmission, reception, and control. At present, the immature automated production line and the high cost of multiple key components are the reasons for the high cost of lidar, and the main path for the cost of lidar in the future is localization, high integration and automated production.

Figure: LiDAR cost composition

Figure: LiDAR cost composition

The maturity of components also facilitates the optimization of the supply chain. Domestic manufacturers can more easily obtain high-quality components, reduce dependence on imported components, and reduce the risk of supply chain disruptions. At the same time, the optimization of the supply chain also further reduces the cost of logistics and time, and improves the overall operational efficiency. With the improvement of the competitiveness of domestic products and the transformation of consumer preferences, the share of domestic products in the domestic market continues to grow. In some fields, such as smart phones, home appliances, new energy vehicles, etc., domestic products have occupied a dominant position. The maturity of upstream components and the reduction of costs have a significant role in promoting the acceleration of domestic penetration. With the continuous progress of technology and the continuous development of the market, domestic products are expected to achieve breakthroughs and surpasses in more fields.

For more info:

The Road to Multi-sensor Fusion Begins (1)

The Road to Multi-sensor Fusion Begins (2)

The Road to Multi-sensor Fusion Begins (3)

The Road to Multi Sensor Fusion Begins (4)