Recommended Introduction: Hot Climate and Automotive Chip Life: An Invisible Challenge

Today, with the accelerated expansion of the global automotive market, chip reliability is becoming the focus of attention inside and outside the industry. Especially in the face of the unique climatic conditions of the tropics, the aging of automotive chips has raised new challenges. Editor-in-Chief of the Journal of Semiconductor Engineering

Ed Sperling's article, "Accelerating Aging of Automotive Chips in Hot Climates", comprehensively analyzes the mechanism behind this phenomenon and how to deal with it, from the micro role of environmental factors to the macro trend of technical solutions.

Taking the high temperature and high humidity characteristics of tropical climate as the starting point, this paper analyzes in detail how these environmental conditions accelerate chip aging. For example, sustained high temperatures pose a threat to the thermal stability of materials, while humidity can cause problems such as circuit corrosion and insulation failure. By citing actual data and cases, the author points out the manifestations of chip aging in terms of performance degradation and system failure.

More importantly, the article does not stop at the surface of the problem, but proposes targeted solutions. For example, optimizing chip packaging materials to enhance heat resistance, improving humidity protection technology, and strengthening environmental adaptability considerations during the design phase are all important ways to alleviate this problem. These contents not only directly hit the pain points of the industry, but also provide important inspiration for future technological innovation.

By reading this article, you will be able to:

1. A deep understanding of the potential impact of tropical climate on automotive chips;

2. Understand the main triggers of chip aging and its impact on automotive electronic systems;

3. Get cutting-edge technology solutions to deal with chip aging problems.

For those in the industry who focus on tropical applications in the global market layout, this article is undoubtedly a professional reference worthy of in-depth study. With detailed data and rigorous analysis, the article opens a window for readers to observe the reliability of automotive chips from a new perspective.

Let's explore this article in depth and discover the challenges and coping strategies faced by automotive chips in tropical climate!

The latest data shows that as global temperatures rise, the lifespan of automotive chips is significantly shortened and may introduce new safety issues.

In high-temperature climates, automotive chips are aging much faster than expected, raising questions about the long-term reliability of electric vehicles and the applicability of advanced process chips in safety-critical applications. Most of today's automotive electronics use ASIL D (Automotive Safety Integrity Level) compliant chips that can operate at temperatures up to 125°C. However, studies have shown that the lifespan of these chips is significantly shortened at sustained high temperatures.

For example, in the study in Phoenix, Arizona, the daytime temperature exceeded 43.3°C for 64 consecutive days, with 5 of those days exceeding 46.1°C. At this temperature, the cabin temperature of a vehicle with a dark interior can reach 93°C, which is close to the boiling point of water. In this environment, the rate of chip aging accelerates dramatically.

Ⅰ.Uncertainty in complex systems

According to a white paper published by the IEEE Functional Safety Standards Committee, it is challenging to predict how complex systems will behave in extreme environments. Environmental factors that affect chip degradation include temperature, humidity, vibration, altitude, and radiation. The dynamic effects of these factors are difficult to quantify, resulting in complex RUL (Remaining Life) models.

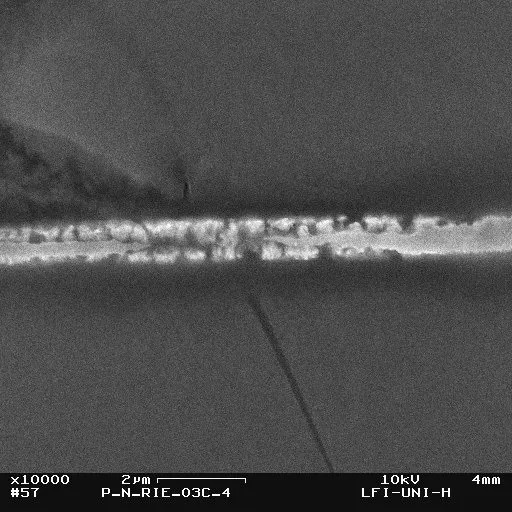

Figure: SEM image of a fault due to electromigration in a copper interconnect with the passivation layer removed

Ⅱ.The dilemma of advanced node chips

Steve Pateras, vice president of marketing at Synopsys, noted that traditional automotive chips use technology from 10 years ago and are less problematic. But today, 5nm and 3nm chips have become mainstream, which requires real-time monitoring of chip health, rather than empirical judgment alone. According to the Arrhenius formula, a high-temperature environment can significantly shorten the chip life. For example, the original design life of a chip with a 30-year life was reduced by an additional 10% per year in the high temperature environment of the Phoenix summer, and the life span was shortened to 26 years after one year.

Ⅲ.Strategies for coping with extreme temperatures

Chipmakers are grappling with the challenges posed by climate change, such as designing new materials, increasing margins, and introducing active cooling mechanisms.

Bill Stewart, Vice President of Infineon Automotive Americas, emphasized that chip quality and functional safety are of paramount importance. The failure rate of its automotive chips is only 60 parts per billion, but the high-temperature environment requires additional design margins. In addition, failure detection and alarm functions (e.g., software or hardware fault diagnosis and fault response mechanisms) within the system need to be ensured.

Satish Ganesan, senior vice president of Synaptics' Intelligent Sensing Division, said that while automotive displays have not yet failed at high temperatures, the failure of other components can cause systemic problems, especially in complex systems, where small failures can lead to total paralysis.

Ⅳ.Technical bottlenecks in thermal environments

As automotive systems become more autonomous, the utilization of their processing units increases significantly, which further increases circuit temperatures and accelerates aging. For example, Infineon's Ray Notarantonio points out that the task model of traditional chips does not take into account the full-time operation mode of the vehicle for long periods of time at high temperatures or autonomous driving, which creates new challenges for chip design and verification.

At the package level, high temperatures can cause solder joints to become brittle, especially in the case of continuous high temperatures or temperature fluctuations, and differences in the coefficient of thermal expansion can trigger mechanical stress, resulting in multiple failure modes such as solder joints, microbumps, electromigration, and dielectric breakdown.

Ⅴ.Predict the future of maintenance and resilient design

Strategies to address these challenges include:

1. Real-time monitoring and predictive maintenance: Monitor performance changes and predict failures by analyzing built-in data from the equipment. For example, AI can be used to adjust chip frequencies to extend lifespan.

2. Design redundancy and dynamic adjustment: While redundant design is difficult to achieve at advanced nodes such as 5nm and 3nm, durability can be improved by improving interconnect structure and material properties.

A future third edition of the ISO 26262 standard will introduce more new requirements for predictive maintenance and system resilience, including real-time monitoring of silicon data and prediction of potential failures. This indicates that automotive chip design is moving towards intelligence and dynamics.

Ⅶ.Conclusion

In the context of increasing climate change, the durability and security of automotive chips are facing great challenges. Through technological innovation and standard optimization, future automotive electronic systems are expected to achieve higher reliability and stability in extreme environments.