Vishay Intertechnology today announced the launch of four new rectifiers, further expanding its seventh-generation 1200V FRED Pt® Fast Recovery Epitaxial Diode (FRED) platform. Housed in the eSMP® family of SMF (DO-219AB) packages, the newly released rectifiers are designed for automotive and industrial applications with an optimized balance between reverse recovery charge (Qrr) and forward voltage drop, while providing lower junction capacitance and shorter recovery times. Available in 1A and 2A current specifications, these new devices are optimized for the needs of electric vehicles (EVs), industrial drives, tools, motors, energy storage systems, and more.

1. High-efficiency rectification, low-loss design

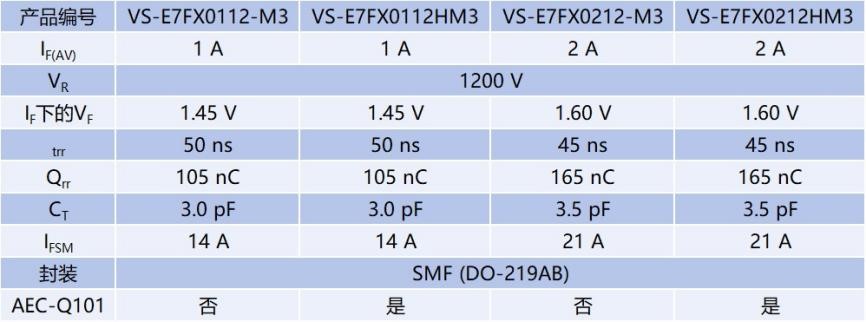

These new rectifiers include the VS-E7FX0112-M3, VS-E7FX0212-M3, VS-E7FX0112HM3, and VS-E7FX0212HM3, with the VS-E7FX0112HM3 and VS-E7FX0212HM3 AEC-Q101 qualified for automotive electronics. Compared to other comparable devices on the market, Vishay's rectifiers offer excellent fast recovery characteristics, which reduce switching losses and improve system efficiency. For example, the device has a reverse recovery charge (Qrr) of as little as 105 nC and a recovery time as short as 45 ns, which greatly improves the efficiency of power conversion and optimizes power consumption and thermal control.

These devices excel in terms of voltage drop (VF), with a VF of 1.45V for the 1A model and 1.60V for the 2A model, which allows for more efficient power conversion in applications, especially in high-frequency switching and high-voltage applications.

Figure: Vishay 1200vFRED-SMF

2. High reliability and high peak current capability

Housed in an SMF (DO-219AB) package, the new rectifier measures just 4.2 mm x 1.4 mm, is 1.08 mm thick, and has a low minimum creepage distance of 2.2 mm. Despite its small size, the rectifier can withstand non-repetitive peak inrush currents (IFSM) of up to 21A, which allows it to provide superior current protection and safe operation in high-voltage applications such as industrial and automotive.

In addition, the package design of these rectifiers optimizes junction capacitance (CT) to 3.0pF for the 1A model and 3.5pF for the 2A model, further reducing switching losses and improving the system's responsiveness. The low junction capacitance design makes the device more stable at high frequencies and is suitable for high-frequency applications that require fast switching.

3. Wide range of applications

These new rectifiers can be used in a wide range of industrial and automotive applications, especially where high-frequency switching and high-efficiency current control are required. For example, the VS-E7FX0112-M3 and VS-E7FX0212-M3 can be used for clamping, buffering, and freewheeling diodes for flyback auxiliary power supplies, while the VS-E7FX0112HM3 and VS-E7FX0212HM3 are automotive-compliant for applications such as on-board chargers, electric motors, and energy storage systems for electric vehicles.

Rectifiers can also be used for high-frequency bootstrap driver functions and desaturation protection of IGBTs (Insulated Gate Bipolar Transistors) and Si/SiC MOSFETs (Silicon Nitride Metal Oxide Semiconductor Field Effect Transistors). In addition, these devices have a wide range of applications in industrial drives and tools, electric vehicle chargers, electric motor control systems, power converters, and LED driver circuits.

4. Reliability and high-temperature operation

Vishay's new rectifiers feature a planar structure and platinum-doped lifetime control technology to optimize performance while ensuring system reliability and stability. Platinum doping technology can extend the lifetime of the device without compromising its performance. The optimized stored charge and low recovery current design not only reduces switching losses, but also helps reduce overall power consumption, which in turn improves the energy efficiency of the system.

The devices are RoHS compliant, halogen-free, have a J-STD-020 standard level 1 moisture sensitivity, and are capable of stable operation in high-temperature environments up to +175°C. As a result, these rectifiers are not only suitable for conventional industrial and automotive applications, but also meet the needs of long-term stable operation in high-temperature environments, especially for applications with high requirements for high temperature resistance and high reliability.

Figure: Vishay Technology's seventh-generation 1200V ultra-fast recovery rectifier device specification table

5. Complete product portfolio and system support

Vishay also offers solutions and tools that are compatible with these rectifiers to help customers achieve faster system development. These include an inverter board to drive a 9-axis motor, a multi-axis motor control software package, and motion utilities that can help engineers quickly build an experimental platform and reduce development time and costs.

Vishay provides extensive support during the product design process, including a dedicated engineering team and development tools, to help customers validate and prototype designs in the shortest possible time. In addition, Vishay's rectifier portfolio has been validated for compatibility with more than 400 successful product combinations, ensuring the stability and reliability of the system architecture and reducing design risk.

6. Summary & Prospects

Vishay's 1A and 2A 7th generation FRED Pt® ultra-fast recovery rectifiers offer significant advantages in terms of reduced switching losses, increased efficiency, and improved system stability. By employing low Qrr, low junction capacitance, and short recovery times, these rectifiers optimize the power conversion process and deliver superior performance in several demanding applications, especially in electric vehicles, industrial drives, tools, and energy storage systems.

With the growing demand for efficient energy management and more efficient power control, Vishay's new rectifiers will be an important part of many industries, driving the continuous advancement of industrial and automotive electronics. These rectifiers are expected to be widely used worldwide in the coming years and become a key component for efficient power conversion and reduced energy consumption.