In today's fast-paced era of technology, the semiconductor industry, as the cornerstone of information technology, is driving the digital transformation of the global economy at an unprecedented speed. However, while the industry pursues technological innovation and production efficiency, it is also facing the challenge of increasing water scarcity. This article aims to explore the impact of water scarcity on the semiconductor industry, the challenges it faces, and the steps that should be taken to address it both inside and outside the industry.

Water scarcity: an invisible threat to the semiconductor industry

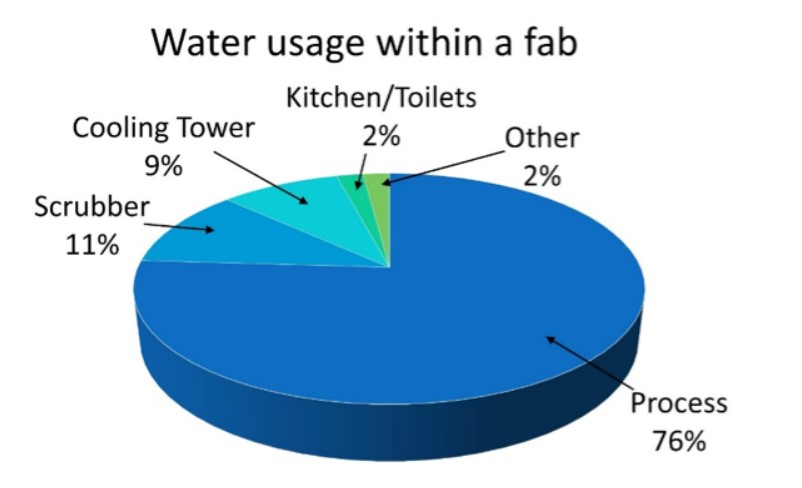

Semiconductor manufacturing is a highly complex and water-intensive process. From wafer cleaning and etching to equipment cooling, water is indispensable in every link. With the continuous advancement of semiconductor technology, the process nodes continue to shrink, and the requirements for water purity and dosage are getting higher and higher. However, the uneven distribution of global water resources, the intensification of pollution, and the frequent occurrence of extreme weather events caused by climate change have made water scarcity increasingly prominent, and it has become an invisible threat that cannot be ignored in the semiconductor industry.

Challenges

Rising production costs: In response to water scarcity, semiconductor manufacturers have had to take a number of measures to ensure water supply, such as buying more water rights and building more efficient wastewater treatment facilities. These additional inputs will undoubtedly increase production costs and affect the profitability of enterprises.

Risks to supply chain stability: Water scarcity can lead to water supply disruptions in some regions, which in turn can affect semiconductor manufacturers' production schedules. This risk is particularly acute for manufacturers who rely on water resources in specific regions, potentially triggering supply chain instability.

Pressure for technological innovation: Faced with the challenge of water scarcity, the semiconductor industry needs to accelerate technological innovation, improve water efficiency and develop new water-saving technologies. However, technological innovation often requires a lot of R&D investment and time accumulation, which is a lot of pressure for enterprises.

Figure: Water consumption in semiconductor manufacturing

Strategies

Improving water efficiency: Semiconductor manufacturers should improve water efficiency by optimizing production processes and improving wastewater treatment technologies. For example, the use of advanced water-saving equipment and technology to reduce water consumption in the production process; Strengthen wastewater recycling and reuse, and reduce dependence on external water resources.

Diversify water supply systems: To reduce reliance on a single source of water, semiconductor manufacturers should diversify their water supply systems. This includes measures such as working with local water authorities, purchasing water rights, and building rainwater harvesting systems. At the same time, companies can also consider deploying production bases on a global scale to diversify water risks.

Strengthen international cooperation and exchanges: In the face of global water shortage, the semiconductor industry should strengthen international cooperation and exchanges. By sharing information on water-saving technologies, management experience, policies and regulations, we will jointly explore effective ways to solve the problem of water shortage. In addition, international cooperation can also help promote the stability of cross-border supply chains.

Promote policy and regulatory support: The government should introduce policies and regulations to encourage and support the adoption of water-saving technologies and measures in the semiconductor industry. For example, providing incentives such as tax incentives and subsidies; develop strict regulations and standards for water management; strengthen water resources supervision and law enforcement. These measures will help drive the semiconductor industry towards a more sustainable and environmentally friendly development.

Water scarcity has become one of the major challenges facing the semiconductor industry. To meet this challenge and ensure the sustainability of the industry, semiconductor manufacturers need to take a range of measures to improve water efficiency, reduce production costs, and ensure supply chain stability. At the same time, strengthening international cooperation and policy support is also the key to solving the problem of water scarcity. Through joint efforts and continuous exploration of the path of innovation, the semiconductor industry will surely find new development opportunities and growth points in the dilemma of water shortage.